2ply/3ply Circle Steel Circle

PuXin Stainless Steel

| Availability: | |

|---|---|

| Quantity: | |

Product Description

| Thickness | 0.18mm-3.0mm or as request | |||

| Diameter | 20mm-850mm or as request | |||

| Grade | 201/202/304/316/409/410/430/610, etc | |||

| Standard | GB/ASTM/JIS/AISI/DIN | |||

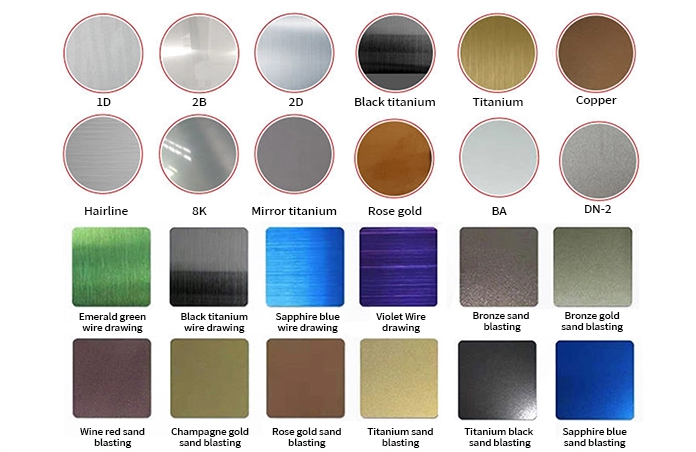

| Surface | 2B/BA/8K/NO4/HL | |||

| Technique | Cold Rolled | |||

| Structure strength | 1.0Mpa, 2.0Mpa, 16.0Mpa, 21.0Mpa, etc | |||

| Material | DDQ, High Copper, Half Copper or Low Copper Material | |||

| Application | Kitchenware, Utensils, Tableware, Household Appliances, Construction Decoration, Daily Products, etc | |||

| MOQ | 1MT | |||

| Sample | Available | |||

| Protection | As per your request | |||

| Packaging Detail | Wooden box, steel belts or as per your request | |||

| Delivery Detail | Within 35 days after deposit or original L/C | |||

| Loading Port | ShangHai Port | |||

| Payment Terms | T/T 30%deposit,balance payment before shipment or L/C at sight | |||

Chemical composition and mechanical properties of stainless steel circle

| Grade | Chemical Composition (%) | Mechanieal Performece | ||||||

| C | Si | Mn | P | S | Ni | Cr | Hardness | |

| 201 | ≤0.15 | ≤1.00 | 5.5/7.5 | ≤0.060 | ≤0.030 | 3.5/5.5 | 16.0/18.0 | HB≤241,HRB≤100, HV≤240 |

| 304 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 8.0/11.0 | 18.00/20.00 | HB≤187,HRB≤90,HV≤200 |

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 10.00/14.00 | 16.0/18.0 | HB≤187, HRB≤90 HV≤200 |

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 10.00/14.00 | 16.0/18.0 | HB≤187, HRB≤90 HV≤200 |

| 410 | ≤0.15 | ≤1.00 | ≤1.25 | ≤0.060 | ≤0.030 | ≤0.060 | 11.5/13.5 | HB≤183, HRB≤88 HV≤200 |

| 430 | ≤0.12 | ≤1.00 | ≤1.25 | ≤0.040 | ≤0.03 | - | 16.00/18.00 | HB≤183, HRB≤88 HV≤200 |

Introduction to stainless steel circle

The corrosion resistance of stainless steel circle mainly depends on its alloy composition (chromium, nickel, titanium, silicon, aluminum, manganese, etc.) and internal organizational structure.

The main role is chromium. Chromium has high chemical stability and can form a passivation film on the surface of steel to isolate the metal from the outside world, protect the steel plate from oxidation, and increase the corrosion resistance of the steel plate. After the passivation film is destroyed, the corrosion resistance decreases.

Application

Making stainless steel circle into pot bases is a common application, especially in the manufacture of stainless steel pans.

First of all, we must choose high-quality stainless steel circle as materials. Stainless steel should be thick enough to ensure wear resistance and even heating of the bottom of the pot. Cut the stainless steel plate into circle of required size. Stainless steel plates can be cut using a cutting machine or laser cutting. Put the cut stainless steel circle into the machine and use high pressure to punch the circle into the concave and convex shape of the bottom of the pot. After pressing, the bottom of the pot needs to undergo a heat treatment process to reduce stress and increase the strength of the material. This helps the bottom of the pot maintain a tight seal during use. To smoothen the bottom of the pot and enhance its appearance, a sanding and polishing process is required. This can be done mechanically. During the production process, the finished pot bottom must be inspected to ensure that it meets quality standards. This includes checking aspects such as flatness, uniformity and wear resistance.

Finally, the manufactured base is often assembled with other pan parts (such as sides, handles, etc.) to create a complete stainless steel pan.

If you are interested in this product, you can also take a look at our other products, our company also produces a variety of stainless steel products, such as stainless steel pipe, stainless steel sheet and so on.

FAQ

Q: Are you a manufacturer or trading company?

A: We are a specialized manufacturer.

Q: Do you accept sample order?

A: Yes sure, please contact us for details.

Q: How does your company control the quality?

A: Qualityfirst. In order to guarantee high quality for our products,

Modern always makes a serious inspection for all products and raw materials in strict procedure.

Q: How about your after-sales service?

A: As a professional steel exporter, we offer promote technology support for all problems and questions.

Besides, we accept goods return or replace for quality problem.

Q: How about discount?

A: Price is based on products and order quantity.

Q: How about the delivery terms?

A:1.Payment: T/T, Western Union, Paypal, 30% deposit in advance and balance before delivery.

2. MOQ: Order Quantity 1 TON, or as required.

3.Transportation: By express (DHL,INT,FedEx),air,sea,and train.

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | N | Other | |

| 201 | 0.15 | 1 | 5.5-7.5 | 0.06 | 0.03 | 3.5-5.5 | 16-18 | - | - | 0.25 | |

| 202 | 0.15 | 1 | 7.5-10 | 0.05 | 0.03 | 1 | 17-19 | - | - | 0.05-0.25 | |

| 301 | 0.15 | 1 | 2 | 0.045 | 0.03 | 6-8 | 16-18 | - | - | 0.1 | |

| 304 | 0.08 | 1 | 2 | 0.045 | 0.03 | 8-11 | 18-20 | - | - | - | |

| 304L | 0.03 | 1 | 2 | 0.045 | 0.03 | 8-12 | 18-20 | - | - | - | |

| 309S | 0.08 | 1 | 2 | 0.045 | 0.03 | 12-15 | 22-24 | - | - | - | |

| 310 | 0.25 | 1.5 | 2 | 0.045 | 0.03 | 19-22 | 24-26 | - | - | - | |

| 310S | 0.08 | 1 | 2 | 0.045 | 0.03 | 19-22 | 24-26 | - | - | - | |

| 316 | 0.08 | 1 | 2 | 0.045 | 0.03 | 10-14 | 16-18 | 2-3 | - | - | |

| 316L | 0.03 | 1 | 2 | 0.045 | 0.03 | 10-14 | 16-18 | 2-3 | - | - | |

| 316Ti | 0.08 | 1 | 2 | 0.045 | 0.03 | 10-14 | 16-18 | 2-3 | 0.1 | Ti≥5C | |

| 317L | 0.03 | 1 | 2 | 0.045 | 0.03 | 11-15 | 18-20 | 3-4 | - | - | |

| 321 | 0.08 | 1 | 2 | 0.045 | 0.03 | 9-12 | 17-19 | - | - | Ti:5c-0.70 | |

| 430 | 0.12 | 1 | 1 | 0.04 | 0.03 | - | - | ||||

| 904L | 0.02 | 1 | 2 | 0.04 | 0.03 | 23-28 | 19-23 | 4-5 | 1-2 | 0.1 | |

| 2205 | 0.03 | 1 | 2 | 0.03 | 0.02 | 4.5-6.5 | 22-23 | 3-3.5 | - | 0.14-0.2 | |

| 254SMO | 0.02 | 0.8 | 1 | 0.03 | 0.01 | 17.5-18.5 | 19.5-20.5 | 6.0-6.5 | - | 0.18-0.25 | |

| 654SMO | 0.02 | 0.5 | 2-4 | 0.03 | 0.005 | 21-25 | 24-25 | 0.3-0.6 | 7-8 | 0.45-0.55 | |

| 253MA | 0.05-0.1 | 1.4-2 | 0.8 | 0.04 | 0.03 | 10-12 | 20-22 | - | - | 0.14-0.2 | ce:0.03-0.08 |

| AL-6XN | 0.03 | 1 | 2 | 0.04 | 0.03 | 23.5-25.5 | 20-22 | 6-7 | 0.75 | 0.18-0.25 | |

| S32750 | 0.03 | 0.8 | 1.2 | 0.035 | 0.02 | 6-8 | 24-26 | 3-5 | 0.5 | 0.24-0.32 | |

| S32760 | 0.03 | 1 | 1 | 0.03 | 0.01 | 6-8 | 24-26 | 3-4 | 0.5-1 | 0.2-0.3 |