| Availability: | |

|---|---|

| Quantity: | |

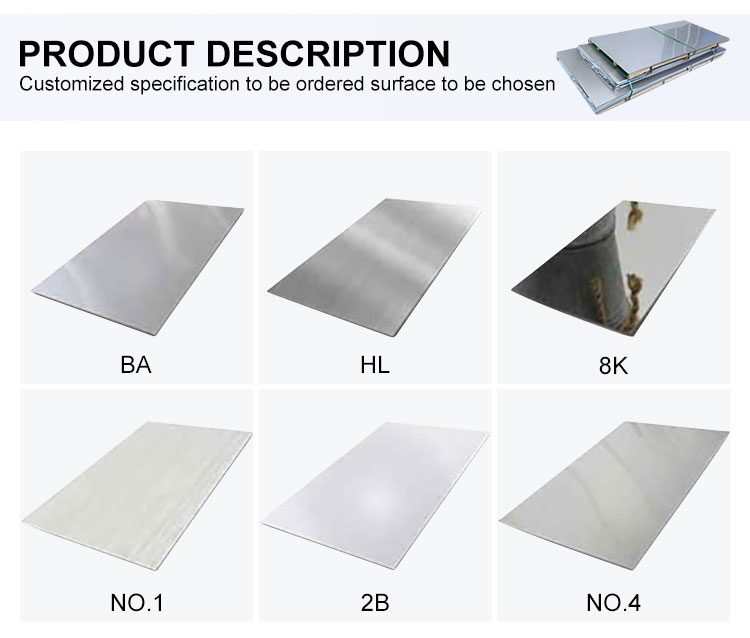

PRODUCT DESCRIPTION

AISI 904L STAINLESS STEEL SHEET / PLATE FOR SALE

Grade:12Cr13;SUS 410;ASTM 410;X12Cr 13;1.4006;S4100;AISI 410

Surface: NO. 1, 2B, BA, NO. 3, NO. 4, HL

MOQ : 5 TON”CHOOSE PUXIN STEEL AND LOOK FORWARD TO HEARING FROM YOU!“

Super austenitic stainless steel (904L stainless steel plate) is a high-alloy, low-carbon high-quality stainless steel designed for harsh corrosive environments, especially for applications under extreme conditions such as chemical industry and marine engineering. Its unique alloy composition includes high chromium and sufficient nickel content, and copper is added, making it excellent in acid resistance, chloride crevice corrosion resistance and stress corrosion cracking.

PRODUCT PERFORMANCE

Features of 904l stainless steel plate

Excellent corrosion resistance

High nickel, chromium and copper alloy composition

Excellent pitting resistance

High temperature environment stability

Good machinability and weldability

Excellent mechanical properties

Wide application

PRODUCT FEATURES

PRODUCT CHARACTERISTICS OF 904l STAINLESS STEEL PLATE

Welding performance: 904L stainless steel plate has good welding performance and is suitable for a variety of welding methods, the most common of which include manual arc welding and inert gas shielded welding. In order to ensure the strength and corrosion resistance of the welded joint, the composition and purity of the welding rod or wire are required to be high, and the molybdenum content must also be higher than that of the parent material. Generally, no preheating is required before welding, but when working in a cold environment, in order to avoid condensation of water vapor, the joint or surrounding area can be evenly heated, and the local temperature should be controlled below 100°C to prevent carbon accumulation and intergranular corrosion. During the welding process, it is recommended to use a small wire energy, continuous, and fast welding rate, and heat treatment is usually not required after welding. If heat treatment is required, it should be heated to 1100-1150°C and then cooled rapidly.

Machining performance: The machinability of 904L stainless steel plate is similar to that of other austenitic stainless steels. Tool adhesion and work hardening may occur during machining. To reduce work hardening, it is recommended to use positive carbide tools and select appropriate cutting coolants, such as sulfide oil or chlorinated oil. During the cutting process, avoid using too slow cutting speed or feed rate to ensure processing efficiency and surface quality.

PRODUCT PARAMETERS

PRODUCT PARAMETERS

| ELEMENT(%) | |

| C | ≤0.03 |

| Si | ≤1.00 |

| Mn | ≤2.00 |

| P | ≤0.035 |

| S | ≤0.03 |

| Ni | 23.0~25.0 |

| Cr | 18.0~20.0 |

| Mo | 3.0~4.0 |

| Cu | 4.0~5.0 |

PHYSICAL PARAMETERS OF 904L STAINLESS STEEL PLATE

Density (g/cm) :8.24g/cm3

Melting point:1300-1390 ℃

Tensile strength Rm N/mm2: 490

Yield strength RP0.2N/mm2: 216

Elongation A5 %: 35

SURFACE TREATMENT

PUXIN STEEL offers 904L stainless steel plates in a variety of thicknesses and sizes, ranging from 0.3mm to 6.0mm. We also provide customized cutting and surface processing services, including options such as mirror, brushed, and sandblasting finishes, to meet the specific needs of our customers.

APPLICATION

Petroleum and petrochemical equipment, such as reactors in petrochemical equipment.

Storage and transportation equipment for sulfuric acid, such as heat exchangers.

Flue gas desulfurization equipment in power plants.

Scrubbers and fans in organic acid treatment systems.

Seawater treatment equipment, seawater heat exchangers, paper industry equipment, sulfuric acid and nitric acid equipment, acid making, pharmaceutical industry and other chemical equipment, pressure vessels, food equipment.

Pharmaceutical factories: centrifuges, reactors.

Plant foods: soy sauce tanks, cooking wine, salt tanks, equipment and dressings.