| Availability: | |

|---|---|

| Quantity: | |

PRODUCT DESCRIPTION

AISI 304l STAINLESS STEEL SHEET| PUXIN METAL

Thickness: HR(2.5.0MM~14.0MM);CR(0.18MM~3.0MM)

Width: 10MM~1800MM

Grade:022Cr19Ni10;SUS 304L;ASTM 304L;S30403;X2CrNi 19-11;1.4306

Classification: Austenitic stainless steel

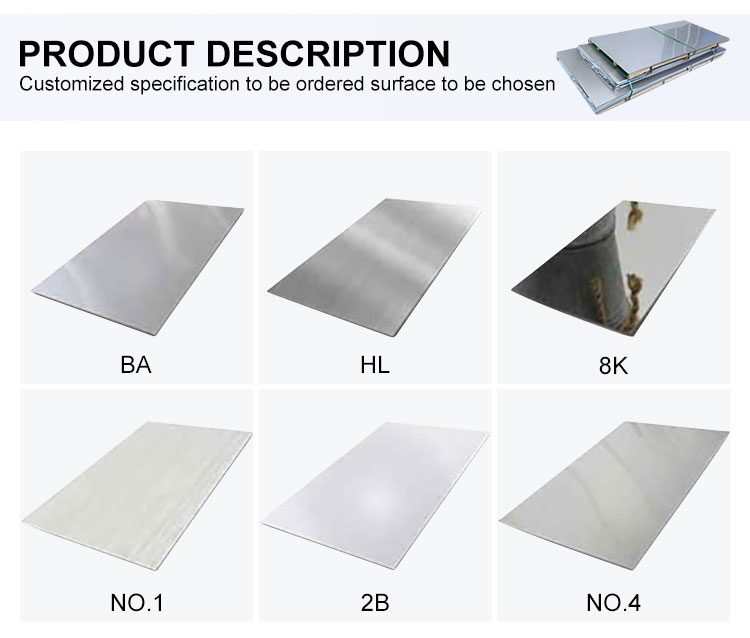

Surface: NO.1、2B、2D、3#、4#、HL、BA

Technique: Hot Rolled & Cold Rolled

Payment terms: L/C T/T (30%DEPOSIT)

Capacity:Monthly shipment volume reaches 4000+ tons

Processing Service:Bending, Welding, Decoiling, Punching, Cutting.

USE:Coal hopper liners, liquid distillation vessels and tomato sauce containers

304L stainless steel plate is a versatile stainless steel material with good comprehensive properties, including corrosion resistance and formability. Its melting point is 1398~1420℃, hardness is HB ≤187 HRB≤90 HV ≤200, and density is 7.93 g/cm3. 304L stainless steel plate is a variant of 304 stainless steel with a lower carbon content, suitable for occasions requiring welding.

Due to the lower carbon content, 304L stainless steel plate reduces the precipitation of carbides during welding, thereby reducing the risk of intergranular corrosion. Therefore, 304L stainless steel plate is particularly suitable for the manufacture of equipment and parts with high corrosion resistance requirements such as coal hopper linings, liquid distillation containers, and tomato sauce containers.

In general, 304L stainless steel plate is a high-quality stainless steel material with good corrosion resistance and welding performance, suitable for manufacturing and processing needs in various industrial fields.

CORROSION RESISTANCE

LOW TEMPERATURE TOUGHNESS

IMPACT TOUGHNESS

FORGEABILITY

WELDABILITY

APPLICATION

As a low-C 304 steel, its corrosion resistance is similar to that of 304 steel in general conditions, but after welding or stress, its resistance to intergranular corrosion is excellent. It can also maintain good corrosion resistance without heat treatment and is generally used below 400 (non-magnetic, operating temperature -196 degrees Celsius to 800 degrees Celsius)

Applied to indoor and outdoor machines, building materials, heat-resistant parts and parts that are difficult to heat treat in the chemical, coal and petroleum industries with high requirements for resistance to intergranular corrosion.

The development of 304L stainless steel has made the corrosion resistance, appearance, processability, strength and other characteristics of 304L stainless steel far exceed those of other materials. Moreover, many surface treatment methods of stainless steel can achieve rich colors and shapes, which has made a great contribution to the development of stainless steel.

Surface treatment methods in the manufacturing process of 304L stainless steel and mechanical grinding surface treatment methods.

SURFACE FINISH

PHYSICAL PROPERTIES

(304L)06CR19NI10 CHEMICAL ELEMENT CONTENT (%)

| Element | Composition (%) |

| Carbon (C) | 0.03 |

| Silicon (Si) | 1.00 |

| Manganese (Mn) | 2.00 |

| Chromium (Cr) | 18~20 |

| Nickel(Ni) | 8~12 |

| Sulfur(S) | 0.030 |

| Phosphorus(P) | 0.045 |

Yield strength: ≥ 205 N/mm²

Tensile strength: ≥ 520 N/mm²

Elongation: ≥ 40%

Hardness:

HB ≤ 187

HRB ≤ 90

HV ≤ 200

Physical properties

Density: 7.93 g/cm³

Specific heat (c, 20℃): 0.502 J/(g·℃)

Thermal conductivity (λ, W/(m·℃)):

20℃: 12.1

100℃: 16.3

500℃: 21.4

Linear expansion coefficient (α, 10⁻⁶/℃):

20~100℃: 16.0

20~200℃: 16.8

20~300℃: 17.5

20~400℃: 18.1

Resistivity: 0.73 Ω·mm²/m

Thermal properties

Melting point: 1398~1420℃

PRODUCT SHOW