| Availability: | |

|---|---|

| Quantity: | |

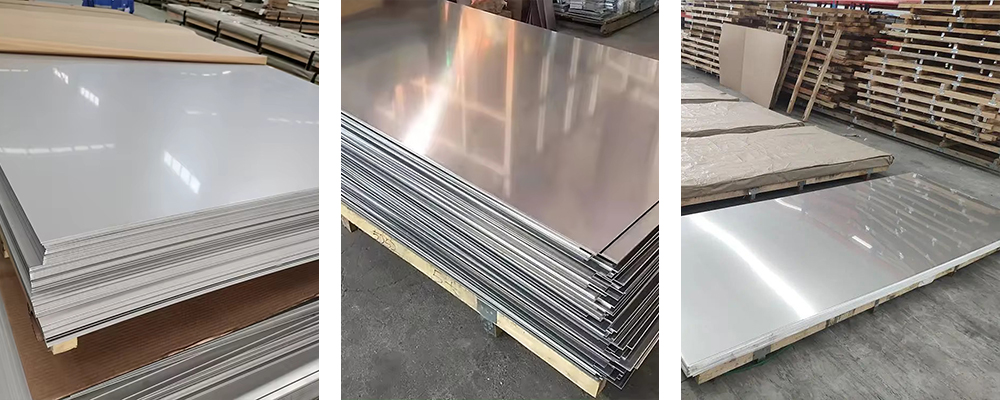

PRODUCT DESCRIPTION

AISI 440A STAINLESS STEEL SHEET / PLATE FOR SALE|PUXIN METAL

Grade:68Cr17;S44070;ASTM 440A;STS 440A;S44002

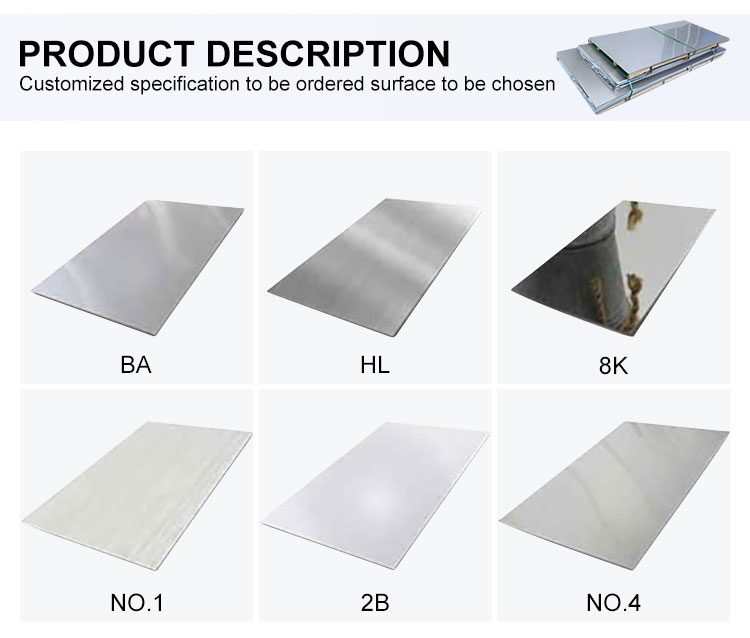

Surface: NO. 1, 2B, BA, NO. 3, NO. 4, HL

MOQ : 5 TON”CHOOSE PUXIN STEEL AND LOOK FORWARD TO HEARING FROM YOU!“

440A stainless steel plate is a high carbon martensitic stainless steel with excellent quenching hardening performance and high hardness. Compared with 440B and 440C stainless steel sheet, 440A has higher toughness. Its carbon content is 0.75%, and it performs well in hardness and corrosion resistance. 440A stainless steel plate has the strongest rust resistance in the 440 series and is widely used in high-demand wear-resistant and corrosion-resistant occasions.

PRODUCT PERFORMANCE

Features of AISI 440A stainless steel plate

High hardness

Good metal mechanical properties

Strong corrosion resistance

PRODUCT FEATURES

PRODUCT CHARACTERISTICS OF 440A STAINLESS STEEL PLATE

Excellent hardness>>440A stainless steel has excellent quench hardening properties and high hardness, suitable for use in applications requiring high strength and wear resistance.

Good toughness>>Compared with 440B and 440C stainless steel sheet, 440A has better toughness and is particularly suitable for applications that require both hardness and impact resistance.

Strong corrosion resistance>>Although 440A is slightly less corrosion-resistant than 440C, it still performs well in most industrial environments.

Wide range of applications>>Widely used in manufacturing tools, bearings, valves, measuring tools, etc., especially in applications requiring high hardness and toughness.

PRODUCT PARAMETERS

PRODUCT PARAMETERS

Carbon C: 0.60~0.75

Manganese Mn: ≤1.00

Silicon Si: ≤1.00

Chromium Cr: 16.0~18.0

Phosphorus P: ≤0.04

Sulfur S: ≤0.03

Molybdenum Mo: ≤0.75

The carbon content and hardness of 440A-440B-440C increase from A-B-C (A-0.75%, B-0.9%, C-1.2%). 440C is an excellent high-end stainless steel with a hardness of 56-58RC. The rust resistance of these three steels is good, 440A is the best, and 440C is the lowest. 440C is very commonly used.

SURFACE TREATMENT

PUXIN METAL offers 440A stainless steel plates in a variety of thicknesses and sizes, ranging from 0.3mm to 6.0mm. We also provide customized cutting and surface processing services, including options such as mirror, brushed, and sandblasting finishes, to meet the specific needs of our customers.

APPLICATION

Precision cutting tools, cutting tools

Bearings and valves

Gages and measuring instruments

Parts with high wear resistance requirements