| Availability: | |

|---|---|

| Quantity: | |

Product Description

| Grade | AISI 430 | Certification | ISO,SGS |

| Shape | Flat | Technique | Cold Rolled &Hot Rolled |

| Surface Treatment | NO. 1, 2B, BA, NO. 3, NO. 4, HL, NO. 8 | MOQ | 10 TON |

| Trading Terms | EXW,Fob,CFR, CIF | Price Terms | L/C,TT |

| Thickness | 0.3-100mm | Width | 500-2000mm or Customized |

| Processing Service | Bending Cutting Welding Punching | Transport Package | Seaworthy Packing for Exporting |

| Origin | China | Production Capacity | 50000 Ton/Year |

| Aplication | Industry Decoration | Delivery Time | 20 days |

Grade:ASTM430,SUS430,S43000,STS430,1.4016,05Crl7

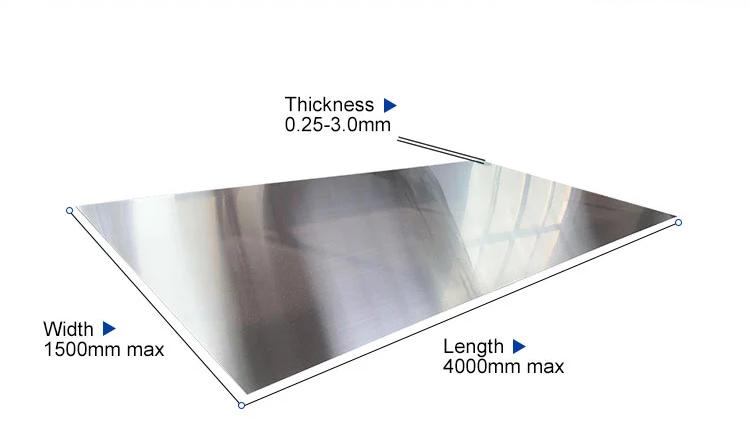

Thickness: 0.25 to 3.0mm

Width: 10-1500mm

Length:1000mm-6000mm, or as per customer's request

Grade:201,301,304,304L,316,316L,410,430

Surface: NO. 1, 2B, BA, NO. 3, NO. 4, HL, NO. 8 and so on

Certification: ISO9001:2015, ISO14001:2015

Delivery time: 15-25 working days

Payment: L/C, D/A, D/P, T/T, Western Union, MoneyGram

Use:Decoration, Elevator, Electric Appliance, Door

AISI 430 Stainless Steel Sheet/Plate| PUXIN STEEL

| AISI 430 Stainless Steel (10Cr17) | |

| Element | Content (%) |

| Carbon (C) | ≤0.12 |

| Silicon (Si) | ≤1.00 |

| Manganese (Mn) | ≤1.00 |

| Phosphorus (P) | ≤0.04 |

| Sulfur (S) | ≤0.030 |

| Chromium (Cr) | 16.00-18.00 |

Introducing the composition and performance of 430 stainless steel plate:

1) Good corrosion resistance;

2) Moderate operating temperature range (up to 815℃);

3) Magnetic in all conditions;

4) Moderate strength at high temperatures;

5) Good weldability.

430 stainless steel is ferritic stainless steel with certain magnetism. Application: decorative materials, lining of household appliances. 430 stainless steel is more suitable for corrosion resistance, durable decoration and structural requirements in general environments, rather than high temperature and heavy load environments.

Application

SUS430 (18Cr) is an economical general-purpose stainless steel with good corrosion resistance. It has excellent processability and stress corrosion resistance and is an ideal alternative to SUS304. As a non-heat-hardened ferritic stainless steel, SUS430 has a low thermal expansion rate and excellent oxidation resistance, and is suitable for use in a variety of scenarios.

Corrosion resistance: In oxidizing acid solutions, especially nitric acid, SUS430 has good corrosion resistance and is suitable for acidic environment applications in the chemical, food and brewing industries.

Stress corrosion resistance: It has good performance in stress corrosion resistance and is suitable for equipment and accessories in corrosive stress environments.

Excellent processability: Easy to form and weld, it is an ideal choice for low cost and no need for heat treatment strengthening.

Low thermal expansion rate: Stable at high temperatures and has good oxidation resistance.

Electronic products and home appliances: Used to manufacture home appliance parts, burner parts and other household appliances.

Tableware and daily necessities: Suitable for products such as tableware, bolts, nuts, screens, etc. that require corrosion resistance and stress corrosion resistance.

Chemical equipment: equipment commonly used in the production of nitric acid, such as absorption towers, heat exchangers, acid tanks, and delivery pipelines.

Architectural decoration and light industry: widely used in architectural decoration parts, household kitchen equipment, and fuel burner parts, providing beautiful and durable solutions.

Stainless steel implementation standards

About US

- Trusted Quality

- Competitive Pricing

- Reliable After-Sales Support

- Fast and Consistent Delivery

- Comprehensive Processing Services

- Flexible Payment Options

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | N | Other | |

| 201 | 0.15 | 1 | 5.5-7.5 | 0.06 | 0.03 | 3.5-5.5 | 16-18 | - | - | 0.25 | |

| 202 | 0.15 | 1 | 7.5-10 | 0.05 | 0.03 | 1 | 17-19 | - | - | 0.05-0.25 | |

| 301 | 0.15 | 1 | 2 | 0.045 | 0.03 | 6-8 | 16-18 | - | - | 0.1 | |

| 304 | 0.08 | 1 | 2 | 0.045 | 0.03 | 8-11 | 18-20 | - | - | - | |

| 304L | 0.03 | 1 | 2 | 0.045 | 0.03 | 8-12 | 18-20 | - | - | - | |

| 309S | 0.08 | 1 | 2 | 0.045 | 0.03 | 12-15 | 22-24 | - | - | - | |

| 310 | 0.25 | 1.5 | 2 | 0.045 | 0.03 | 19-22 | 24-26 | - | - | - | |

| 310S | 0.08 | 1 | 2 | 0.045 | 0.03 | 19-22 | 24-26 | - | - | - | |

| 316 | 0.08 | 1 | 2 | 0.045 | 0.03 | 10-14 | 16-18 | 2-3 | - | - | |

| 316L | 0.03 | 1 | 2 | 0.045 | 0.03 | 10-14 | 16-18 | 2-3 | - | - | |

| 316Ti | 0.08 | 1 | 2 | 0.045 | 0.03 | 10-14 | 16-18 | 2-3 | 0.1 | Ti≥5C | |

| 317L | 0.03 | 1 | 2 | 0.045 | 0.03 | 11-15 | 18-20 | 3-4 | - | - | |

| 321 | 0.08 | 1 | 2 | 0.045 | 0.03 | 9-12 | 17-19 | - | - | Ti:5c-0.70 | |

| 430 | 0.12 | 1 | 1 | 0.04 | 0.03 | - | - | ||||

| 904L | 0.02 | 1 | 2 | 0.04 | 0.03 | 23-28 | 19-23 | 4-5 | 1-2 | 0.1 | |

| 2205 | 0.03 | 1 | 2 | 0.03 | 0.02 | 4.5-6.5 | 22-23 | 3-3.5 | - | 0.14-0.2 | |

| 254SMO | 0.02 | 0.8 | 1 | 0.03 | 0.01 | 17.5-18.5 | 19.5-20.5 | 6.0-6.5 | - | 0.18-0.25 | |

| 654SMO | 0.02 | 0.5 | 2-4 | 0.03 | 0.005 | 21-25 | 24-25 | 0.3-0.6 | 7-8 | 0.45-0.55 | |

| 253MA | 0.05-0.1 | 1.4-2 | 0.8 | 0.04 | 0.03 | 10-12 | 20-22 | - | - | 0.14-0.2 | ce:0.03-0.08 |

| AL-6XN | 0.03 | 1 | 2 | 0.04 | 0.03 | 23.5-25.5 | 20-22 | 6-7 | 0.75 | 0.18-0.25 | |

| S32750 | 0.03 | 0.8 | 1.2 | 0.035 | 0.02 | 6-8 | 24-26 | 3-5 | 0.5 | 0.24-0.32 | |

| S32760 | 0.03 | 1 | 1 | 0.03 | 0.01 | 6-8 | 24-26 | 3-4 | 0.5-1 | 0.2-0.3 |