200 Series/300 Series/400 Series

PUXIN

| Availability: | |

|---|---|

| Quantity: | |

Product Description

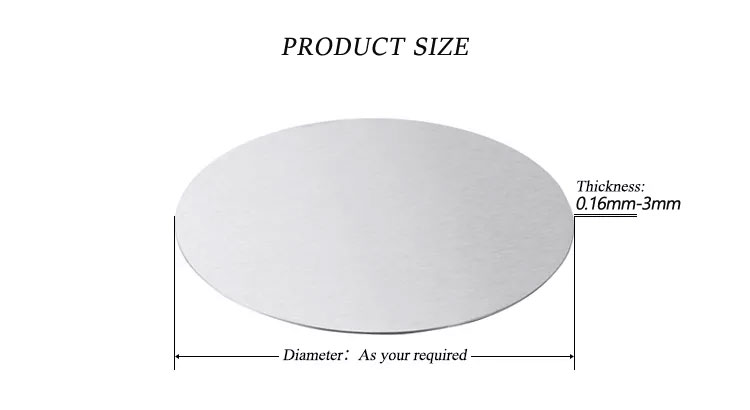

| Product Name | Stainless Steel Circle |

| Standard | JIS/AISI/ASTM/DIN/EN/GB. |

| Surface | 2b/No.1/No.4/mirror/8K/polish/ba/bursh |

| Material | 201,202 |

| Application Range | Decorative,Industry,etc |

| OD | 100mm~800mm |

| Thickness | 3mm ~16mm(or as your requirement) |

Product Introduction

Stainless steel discs contain a variety of alloy components (chromium, nickel, titanium, silicon, aluminum, manganese) and have excellent wear resistance. Chromium has high chemical stability and can form a passivation film with air on the steel surface to isolate the metal from the outside world, protect the steel plate from oxidation, and increase the corrosion resistance of the steel plate.

Chemical Composition

| Grade | C | Mn | P | S | Si | Cr | Ni |

| 201 | ≤0.15 | 5.5~7.5 | ≤0.050 | ≤0.03 | ≤1.00 | 16.0~18.0 | 3.5~5.5 |

| 202 | ≤0.15 | 7.5~10 | ≤0.060 | ≤0.03 | ≤1.00 | 17.0~19.0 | 4.0~6.0 |

| 301 | ≤0.15 | ≤2.00 | ≤0.045 | ≤0.03 | ≤1.00 | 16.5~18.0 | 6.0~8.0 |

| 302 | ≤0.15 | ≤2.00 | ≤0.045 | ≤0.03 | ≤1.00 | 17.0~19.0 | 8.0~10.0 |

| 304 | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤1.00 | 18.0~20.0 | 8.0~10.5 |

| 304L | ≤0.03 | ≤2.00 | ≤0.045 | ≤0.03 | ≤1.00 | 18.0~20.0 | 8.0~12.0 |

| 308 | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤1.00 | 18.0~21.0 | 10.0~12.0 |

| 310S | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤1.00 | 24.0~26.0 | 19.0~22.0 |

| Surface finish | Definition | Application |

| 2B | Those finishedafter cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipmentFood industry Construction materialKitchen utensils. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils,Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils,Building construction,Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction |

| BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils,Electric equipment,Building construction. |

Product Display

FAQ

Q: Are you a manufacturer or trading company?

A: We are a specialized manufacturer.

Q: Do you accept sample order?

A: Yes sure, please contact us for details.

Q: How does your company control the quality?

A: Qualityfirst. In order to guarantee high quality for our products,

Modern always makes a serious inspection for all products and raw materials in strict procedure.

Q: How about your after-sales service?

A: As a professional steel exporter, we offer promote technology support for all problems and questions.

Besides, we accept goods return or replace for quality problem.

Q: How about discount?

A: Price is based on products and order quantity.

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | N | Other | |

| 201 | 0.15 | 1 | 5.5-7.5 | 0.06 | 0.03 | 3.5-5.5 | 16-18 | - | - | 0.25 | |

| 202 | 0.15 | 1 | 7.5-10 | 0.05 | 0.03 | 1 | 17-19 | - | - | 0.05-0.25 | |

| 301 | 0.15 | 1 | 2 | 0.045 | 0.03 | 6-8 | 16-18 | - | - | 0.1 | |

| 304 | 0.08 | 1 | 2 | 0.045 | 0.03 | 8-11 | 18-20 | - | - | - | |

| 304L | 0.03 | 1 | 2 | 0.045 | 0.03 | 8-12 | 18-20 | - | - | - | |

| 309S | 0.08 | 1 | 2 | 0.045 | 0.03 | 12-15 | 22-24 | - | - | - | |

| 310 | 0.25 | 1.5 | 2 | 0.045 | 0.03 | 19-22 | 24-26 | - | - | - | |

| 310S | 0.08 | 1 | 2 | 0.045 | 0.03 | 19-22 | 24-26 | - | - | - | |

| 316 | 0.08 | 1 | 2 | 0.045 | 0.03 | 10-14 | 16-18 | 2-3 | - | - | |

| 316L | 0.03 | 1 | 2 | 0.045 | 0.03 | 10-14 | 16-18 | 2-3 | - | - | |

| 316Ti | 0.08 | 1 | 2 | 0.045 | 0.03 | 10-14 | 16-18 | 2-3 | 0.1 | Ti≥5C | |

| 317L | 0.03 | 1 | 2 | 0.045 | 0.03 | 11-15 | 18-20 | 3-4 | - | - | |

| 321 | 0.08 | 1 | 2 | 0.045 | 0.03 | 9-12 | 17-19 | - | - | Ti:5c-0.70 | |

| 430 | 0.12 | 1 | 1 | 0.04 | 0.03 | - | - | ||||

| 904L | 0.02 | 1 | 2 | 0.04 | 0.03 | 23-28 | 19-23 | 4-5 | 1-2 | 0.1 | |

| 2205 | 0.03 | 1 | 2 | 0.03 | 0.02 | 4.5-6.5 | 22-23 | 3-3.5 | - | 0.14-0.2 | |

| 254SMO | 0.02 | 0.8 | 1 | 0.03 | 0.01 | 17.5-18.5 | 19.5-20.5 | 6.0-6.5 | - | 0.18-0.25 | |

| 654SMO | 0.02 | 0.5 | 2-4 | 0.03 | 0.005 | 21-25 | 24-25 | 0.3-0.6 | 7-8 | 0.45-0.55 | |

| 253MA | 0.05-0.1 | 1.4-2 | 0.8 | 0.04 | 0.03 | 10-12 | 20-22 | - | - | 0.14-0.2 | ce:0.03-0.08 |

| AL-6XN | 0.03 | 1 | 2 | 0.04 | 0.03 | 23.5-25.5 | 20-22 | 6-7 | 0.75 | 0.18-0.25 | |

| S32750 | 0.03 | 0.8 | 1.2 | 0.035 | 0.02 | 6-8 | 24-26 | 3-5 | 0.5 | 0.24-0.32 | |

| S32760 | 0.03 | 1 | 1 | 0.03 | 0.01 | 6-8 | 24-26 | 3-4 | 0.5-1 | 0.2-0.3 |