| Availability: | |

|---|---|

| Quantity: | |

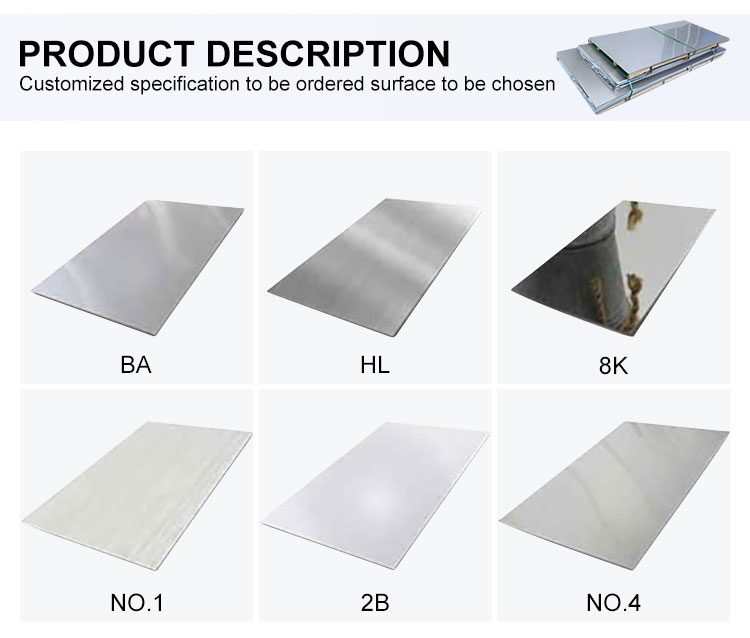

PRODUCT DESCRIPTION

AISI 310S STAINLESS STEEL SHEET / PLATE FOR SALE

”CHOOSE PUXIN STEEL AND LOOK FORWARD TO HEARING FROM YOU!“

AISI 310S stainless steel plate is an austenitic stainless steel belonging to the 25Cr-20Ni series. It has excellent high-temperature oxidation resistance and is suitable for making various furnace components. The maximum temperature is 1200℃ and the continuous use temperature is 1150℃. Application: furnace materials, materials for automobile purification devices.

PRODUCT PERFORMANCE

Features of 2520 (310S) stainless steel plate

Good oxidation resistance;

Wide operating temperature range (below 1150℃);

Non-magnetic in solid solution state;

High high temperature strength;

Good weldability.

PRODUCT FEATURES

PRODUCT CHARACTERISTICS OF 310S STAINLESS STEEL PLATE

AISI 310S stainless steel is an austenitic chromium-nickel stainless steel with excellent oxidation resistance and corrosion resistance. The high content of chromium and nickel increases the creep strength of the material, allowing it to work stably for a long time at high temperatures. Because it is rich in nickel (Ni) and chromium (Cr), AISI 310S stainless steel has excellent performance in oxidation resistance, corrosion resistance, acid and alkali resistance, and high temperature resistance, and is especially suitable for use in the manufacture of equipment in high-temperature environments such as electric furnace tubes.

Adding an appropriate amount of carbon to austenitic stainless steel can significantly increase the strength of the material through solid solution strengthening. At the same time, by adding elements such as molybdenum, tungsten, niobium and titanium, it has excellent high temperature resistance. The face-centered cubic structure of this type of stainless steel gives the material high strength and creep strength under high temperature conditions, making it an ideal high-temperature resistant metal material.

| GRADE | ELEMENT | CHARACTERISTIC | OPERATING TEMPERATURE | USE |

| 253MA | - | Excellent high temperature resistance, oxidation resistance, creep resistance | Applicable to high temperature environments | High temperature parts such as boilers, steam turbines, industrial furnaces, petrochemical equipment, etc. |

| 309S | 0Cr23Ni13 | Can withstand repeated heating below 980℃, with high high temperature strength, oxidation resistance and carburization resistance | ≤980℃ | Various furnace materials |

| 310S | 0Cr25Ni20 | Suitable for making furnace components, the maximum operating temperature is ≤1200℃, and the continuous working temperature can reach 1150℃ | ≤1200℃(continuous 1150℃) | Furnace materials, automobile purification devices |

SURFACE TREATMENT

PUXIN STEEL offers AISI 310S stainless steel plates in a variety of thicknesses and sizes, ranging from 0.3mm to 6.0mm. We also provide customized cutting and surface processing services, including options such as mirror, brushed, and sandblasting finishes, to meet the specific needs of our customers.

APPLICATION

Industrial furnaces and heating devices.

Heat exchangers.

Petroleum and chemical equipment.

Automobile exhaust purification equipment.

Food processing equipment.

Aerospace and aerospace equipment.

Power generation equipment.

Why Choose Us?

15 years of export experience in the steel industry.

Stock volume over 100,000 tons.

Designated supplier for government construction projects.

Products are exported to Russia, the Middle East, Southeast Asia, South Africa, South America and other regions.