| Availability: | |

|---|---|

| Quantity: | |

PRODUCT DESCRIPTION

AISI 321 STAINLESS STEEL SHEET| PUXIN METAL

Thickness: HR(2.5.0MM~14.0MM);CR(0.18MM~3.0MM)

Width: 10MM~1800MM

Grade:06Cr18Ni11Ti;SUS 321;STS 321;ASTM 321;X6CrNiTi 18-10;1.4541;2337

Standard:GB/T4238、ASTM/ASME、 JIS G4305、EN10088、BSEN10028、GB/T3280、GB/T4237

Surface: NO.1、2B、2D、3#、4#、HL、BA

Technique: Hot Rolled & Cold Rolled

Payment terms: L/C T/T (30%DEPOSIT)

Capacity:Monthly shipment volume reaches 4000+ tons

Processing Service:Bending, Welding, Decoiling, Punching, Cutting.

USE:Aircraft jet pipes, boiler shells, process equipment, expansion joints, vertical furnaces, firewalls, buffer joints and pressure vessels.

As an austenitic stainless steel material containing titanium stabilizing elements, 321 stainless steel plate has shown excellent comprehensive advantages in the industrial field by virtue of its core alloy ratio of 18% chromium and 8% nickel and the precise combination of titanium elements. The addition of titanium elements not only effectively inhibits the precipitation of chromium carbide at the grain boundary and significantly improves the resistance to grain boundary corrosion, but also gives the material excellent anti-sensitization performance in the high temperature range of 500-800℃, making it the preferred material for the manufacture of open-air equipment in harsh environments such as the chemical industry, coal mining, and petroleum refining.

321 stainless steel is particularly outstanding in high temperature stability. Its high temperature stress fracture performance and anti-creep performance exceed conventional 304 stainless steel. It can still maintain high strength and structural stability under continuous high temperature conditions. It is particularly suitable for the manufacture of heat exchanger pipes, high temperature piping systems, and complex heat-resistant parts that cannot be heat treated. For the corrosive environment of oxidizing media, 321 stainless steel plates show super tolerance in organic acid and inorganic acid media of different concentrations and temperatures, and can be widely used in key parts such as acid storage tank linings, wear-resistant transmission pipelines, and chemical reaction devices.

Compared with 316L stainless steel, 321 material has significant advantages in high temperature strength and thermal stability; compared with traditional 304 stainless steel, its intergranular corrosion resistance is significantly improved after titanium stabilization treatment, which is especially suitable for welded parts and field equipment exposed to corrosive atmosphere for a long time. This series of characteristics makes 321 stainless steel plate an industrial solution that takes into account corrosion resistance, high temperature mechanical properties and processing feasibility, and continues to serve the core equipment manufacturing in the fields of energy mining, chemical manufacturing, and building materials production.

304 stainless steel plate has beautiful surface and diverse usage possibilities

Good corrosion resistance, longer lasting than ordinary steel

High strength, so thin plates can be used

High temperature oxidation resistance and high strength, so it can resist fire

Processing at room temperature, that is, easy plastic processing

Since no surface treatment is required, it is simple and easy to maintain

Clean and smooth

Good welding performance.

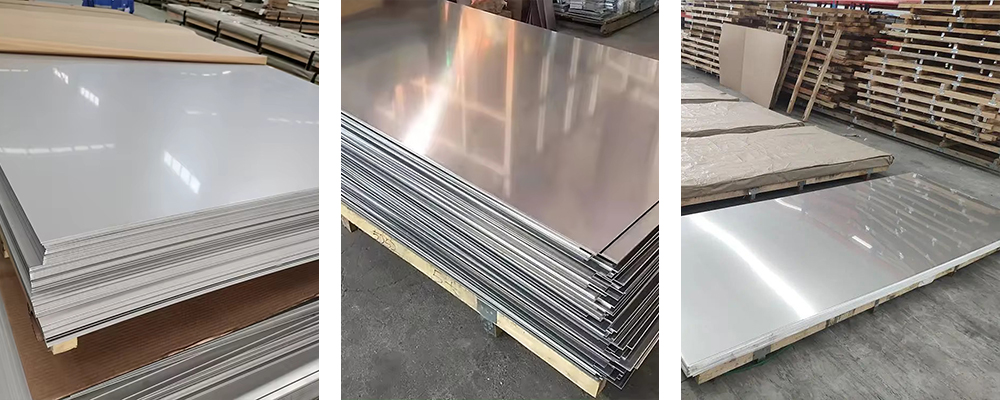

PRODUCT SHOW

CHEMICAL COMPOSITION

Element | Composition (%) |

Carbon (C) | 0.08 |

Silicon (Si) | 1.00 |

Manganese (Mn) | 2.00 |

Chromium(Cr) | 17~19 |

Nickel(Ni) | 9.0~12.0 |

Sulfur(S) | 0.03 |

Phosphorus(P) | 0.045 |

| N | 0.1 |

| Ti | 0.5~0.7 |

MECHANICAL PROPERTY

Yield Strength (Mpa) | ≥205 |

Tensile strength (Mpa) | ≥520 |

Elongation (%) | ≥ 40 |

Hardness | HB ≤187 HRB ≤ 90 |

APPLICATION

1. Petroleum waste gas combustion pipeline

2. Engine exhaust pipe

3. Boiler shell, heat exchanger, heating furnace parts

4. Diesel engine silencer parts

5. Boiler pressure vessel

6. Chemical transport vehicle

7. Expansion joint

8. Spiral welded pipe for furnace pipeline and dryer

1.Petroleum waste gas combustion pipeline:

Application scenario: Exhaust gas treatment system in petroleum processing plants.

Material recommendations: High temperature and pressure resistant stainless steel, such as Austenitic stainless steel or nickel-based alloys.

2.Engine exhaust pipe:

Application scenario: exhaust system of internal combustion engine.

Material recommendations: High temperature alloys such as Inconel or titanium alloys to resist high temperature corrosion and mechanical stress.

3.Boiler shell, heat exchanger, heating furnace components:

Application scenarios: thermal energy equipment and heat exchange systems.

Material recommendations: alloy steel, heat-resistant alloy or stainless steel, depending on temperature and medium.

4.Silencer parts for diesel engines:

Application scenario: Diesel engine exhaust system.

Material recommendations: Stainless steel or other high temperature alloys to resist high temperature corrosion and noise absorption.

5.Boiler pressure vessel:

Application scenario: industrial boiler system.

Material recommendation: pressure vessel steel, such as SA516-70 or other high temperature and high pressure resistant materials.

6.Chemical transport truck:

Application scenario: chemical transportation and storage.

Material recommendations: Corrosion-resistant stainless steel or fiberglass.

7.Expansion joint:

Application scenario: Pipeline connections require a certain degree of scalability.

Material recommendations: stainless steel, copper alloy or rubber with elastic material.

8.Spiral welded pipes for furnace pipes and dryers:

Application scenarios: high temperature combustion systems and industrial dryers.

Material recommendations: high temperature resistant alloys such as Inconel or other special alloys.

9.Aircraft:

Application scenarios: aircraft structures and engine components.

Material recommendations: Aerospace-grade alloys such as titanium alloys, aluminum alloys, and high-temperature alloys

FAQ

Q1: What is your terms of payment?

A: 30% T/T in advance, the balance 70% before delivery. We will show you the photos of products and package before you pay the balance.

Q2: What is your delivery time?

A: For stocks, we could transport the goods to loading port within 7 days after we received your deposit. For production period,it usually takes about 15 days-30 days after receiving the deposit.

Q3: Could you provide the samples?

A: yes, we could provide the free samples on conditons it is available in stocks, however, the the transportation fee is borne by buyer.

Q5: How could you guarantee your products?

A: Each piece of products is manufactured by certified workshops, inspected by Lenser piece by piece according to national QA/QC standard. We also could issue the warranty to customer to guarantee the quality.