| Availability: | |

|---|---|

| Quantity: | |

PRODUCT DESCRIPTION

AISI 410 STAINLESS STEEL SHEET / PLATE FOR SALE

Grade:12Cr13;SUS 410;ASTM 410;X12Cr 13;1.4006;S4100;AISI 410

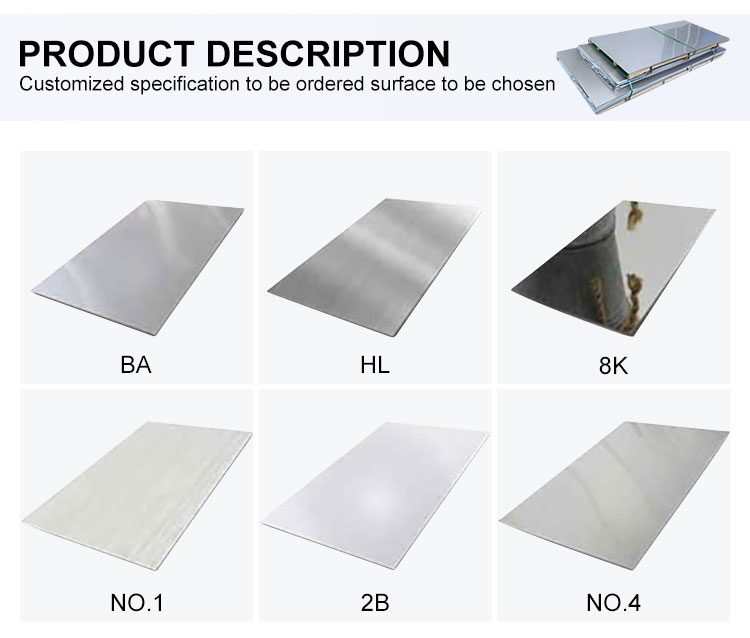

Surface: NO. 1, 2B, BA, NO. 3, NO. 4, HL

MOQ : 5 TON”CHOOSE PUXIN STEEL AND LOOK FORWARD TO HEARING FROM YOU!“

SUS410 stainless steel is a nickel-free martensitic stainless steel with excellent hardenability and hardness. It has high toughness and corrosion resistance, as well as good heat strength and cold deformation properties, and is suitable for use in various environments. In addition, SUS410 stainless steel also has good shock absorption properties.

In order to optimize the performance of 410 stainless steel plate, it is recommended to temper it at high or low temperatures to improve its mechanical properties and corrosion resistance. However, it should be noted that tempering between 370-560℃ should be avoided to avoid affecting its performance and structure. Through reasonable processing and use, SUS410 stainless steel plate can play its best performance and meet various application requirements.

PRODUCT PERFORMANCE

Features of S4100 stainless steel plate

High strength;

Excellent machinability;

Hardened after heat treatment;

Magnetic;

Not suitable for harsh corrosive environments;

PRODUCT FEATURES

PRODUCT CHARACTERISTICS OF 410 STAINLESS STEEL PLATE

HIGH STRENGTH AND LIGHT WEIGHT>>SUS410 stainless steel has high strength and relatively light weight, can absorb impact energy, improve safety performance, and is suitable for the automotive transportation industry.

ANTI-OXIDATION AND CORROSION RESISTANCE>>SUS410 stainless steel contains 11%~30% chromium, has good oxidation resistance and corrosion resistance, and is suitable for manufacturing parts resistant to atmospheric, water vapor, water and oxidizing acid corrosion.

EXCELLENT THERMAL CONDUCTIVITY AND STRESS CORROSION RESISTANCE>>SUS410 stainless steel has a large thermal conductivity, a small expansion coefficient and excellent stress corrosion resistance, and is suitable for use in various environments.

APPLICATION OF OUT-OF-FURNACE REFINING TECHNOLOGY>>Through out-of-furnace refining technology (AOD or VOD), the content of interstitial elements such as carbon and nitrogen can be reduced, and the performance and application range of SUS410 stainless steel can be improved.

PRODUCT PARAMETERS

| ELEMENT | C | Si | Mn | P | S | Cr |

| Maximum(%) | 0.15 | 1.00 | 1.00 | 0.04 | 0.030 | 11.5~13.5 |

| Minimum%(%) | 0.045 | 0.45 | 0.50 | 0.020 | 0.001 | 13.0 |

PHYSICAL PARAMETERS OF 410 STAINLESS STEEL PLATE

Density (g/cm) : 7.70

Magnetic properties : Yes

Specific heat 25℃ (J/kg.℃) : 460

Thermal conductivity 100℃ (W/m.℃) : 24.9

Thermal expansion coefficient 20~100℃ (10/℃) : 9.9

MECHANICAL PARAMETERS OF 410 STAINLESS STEEL PLATE

Ys (Mpa)≥ 205

Ts (Mpa)≥ 440

El (%)≥ 20

Hv≤ 210

SURFACE TREATMENT

PUXIN STEEL offers SUS410 stainless steel plates in a variety of thicknesses and sizes, ranging from 0.3mm to 6.0mm. We also provide customized cutting and surface processing services, including options such as mirror, brushed, and sandblasting finishes, to meet the specific needs of our customers.

APPLICATION

Manufacturing parts resistant to corrosion by the atmosphere, water vapor, water and oxidizing acids

General blades, mechanical parts

Class 1 tableware (spoon, fork, knife, etc.)