| Availability: | |

|---|---|

| Quantity: | |

PRODUCT DESCRIPTION

STAINLESS STEEL CIRCLE | PUXIN METAL

size:According to customer requirements

Standard:ASTM ;AISI;JIS;UNS;EN

Grade:201/304/316L/317/310S/321/2205/430/441/443

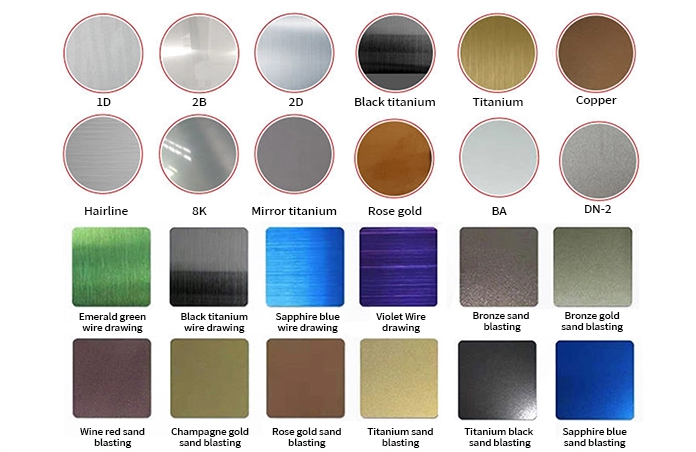

Surface: NO. 1, 2B, BA, NO. 3, NO. 4, HL

MOQ : 5 TON

Edge: Smooth

Material: stainless steelStainless steel circle plates are crafted from premium-grade stainless steel sheets using precision-engineered molds and advanced pressing techniques. We specialize in customizing circular molds to meet specific size and thickness requirements tailored to our clients' needs. Each stainless steel sheet is meticulously positioned within the mold and then shaped with high-precision presses or punches to ensure impeccable geometric form and dimensional accuracy. Following the forming process, the stainless steel circles undergo professional surface treatment and polishing, resulting in a flawlessly smooth finish. The corrosion resistance of these stainless steel circles is primarily determined by their alloy composition, which includes elements such as chromium, nickel, titanium, silicon, aluminum, and manganese, as well as their internal microstructure. Chromium plays a pivotal role by forming a protective passivation layer on the steel's surface, effectively shielding the metal from external oxidation and significantly enhancing its corrosion resistance. If this passivation layer is compromised, the material's resistance to corrosion is reduced.

STAINLESS STEEL CIRCLE PLATES CAN BE USED INDOORS AND OUTDOORS. THEY WILL NOT RUST.

STAINLESS STEEL ROUND PLATES ARE DURABLE

CAN BE CUT WITH AN ANGLE GRINDER

STAINLESS STEEL PLATES HAVE A GOOD GRINDING SURFACE.

PLATES COME WITH A PROTECTIVE FILM.

CAN BE FORMED BY HEATING

NOTE: This sheet is not magnetic. Click here to order magnetic sheet

PRODUCT SHOW

SURFACE FINISH

APPLICATION

Stainless steel circles are widely used in the production of pot bases, particularly in the manufacturing of stainless steel pans. The process begins with selecting high-quality stainless steel circles, ensuring the material is sufficiently thick to guarantee durability and even heat distribution across the pot base. The stainless steel plate is precisely cut into the required circular size using advanced cutting machines or laser technology. The cut stainless steel circle is then placed into a high-pressure machine, where it is molded into the concave and convex shape of the pot base. After pressing, the base undergoes a heat treatment process to reduce internal stress and enhance material strength, ensuring a tight seal during use. To achieve a smooth finish and improve aesthetics, the pot base is mechanically sanded and polished. Throughout production, rigorous quality inspections are conducted to verify flatness, uniformity, and wear resistance, ensuring each base meets strict standards. Finally, the completed pot base is assembled with other pan components, such as sides and handles, to create a fully functional stainless steel pan. If you’re interested in this product, we invite you to explore our extensive range of stainless steel offerings, including stainless steel pipes and sheets, designed to meet diverse industrial and commercial needs.