| Availability: | |

|---|---|

| Quantity: | |

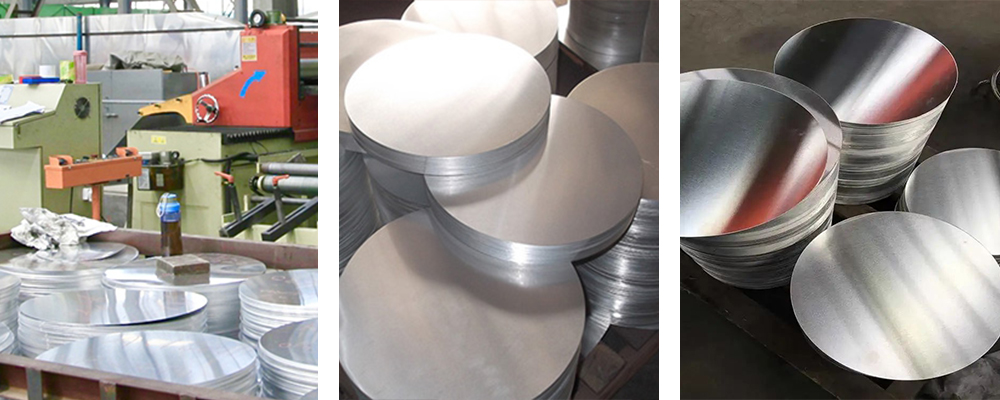

PRODUCT DESCRIPTION

STAINLESS STEEL TRIPLY CIRCLE MANUFACTURER | PUXIN METAL

size:Support customization

SS Grade:201;304;316;316l;410;430

Standard:ASTM ;AISI;JIS;UNS;EN

Surface: 2B;BA;NO.1;HL;8K

MOQ : 5 TON

Stock:Enough

IF YOU NEED OTHER SIZES, PLEASE CONTACT US FOR MORE INFORMATION.

Triply Circle/3 Ply Circle/Aluminum+Stainless Steel Circle is a multi-layer metal composite material for kitchenware. It uses a three-layer structure, including aluminum, stainless steel, and aluminum to ensure excellent heat conduction performance and durability. The aluminum layer provides fast and uniform heat conduction, the stainless steel layer provides corrosion resistance and easy cleaning, and the aluminum layer enhances the structural strength of the product.

The circular design of this 3-layer composite material is suitable for various kitchenware manufacturing, such as pots, pans, woks, etc. It can heat food quickly and evenly, ensuring that the food is cooked more evenly and deliciously. At the same time, the corrosion resistance of the stainless steel layer also makes cleaning more convenient and quick.

Our Triply Circle/3 Ply Circle/Aluminum+Stainless Steel Circle is a high-quality kitchenware material designed to provide you with a premium cooking experience and durability.

SPECIFICATIONS:

Diameter: 50mm, 80mm, 100mm, 120mm, 150mm, 200mm, 250mm, 300mm (other sizes can be customized)

Thickness: 0.5mm, 1mm, 1.5mm, 2mm, 2.5mm, 3mm, 4mm, 5mm (other thicknesses can be customized)

PRODUCT PERFORMANCE

Features of stainless steel Triply Circle

Thermal conductivity

Durable

Structural stability

Multi-purpose kitchenware raw material manufacturing

PRODUCT FEATURES

PRODUCT CHARACTERISTICS OF STAINLESS STEEL TRIPLY CIRCLE MANUFACTURER

Three-layer structure: The three-layer structure of aluminum, stainless steel and aluminum ensures excellent heat conduction performance and durability.

Fast and even heating: The aluminum layer provides fast and even heat conduction, ensuring that food is cooked more evenly and deliciously.

Corrosion resistance: The stainless steel layer has excellent corrosion resistance and is easy to clean.

Structural strength: The aluminum layer enhances the structural strength of the product, ensuring the stability and durability of the product.

Versatile design: Suitable for various kitchenware manufacturing, such as pots, pans, woks, etc., providing a variety of cooking options.

High-quality materials: Adopt high-quality multi-layer metal composite materials to ensure the quality and durability of the product.

SURFACE TREATMENT

| Surface Finish | Definition | Application | |

| 2B | Finished by heat treatment , picking or equipvalent cold rolling , followed by skin pass to obtain adequate luster surface. | With bright and smooth surface ,easy for further grinding to obtain brighter surface ,suitable for medical instruments ,milk containers ,tableware and so on. | |

| BA | Bright heat treatment after cold rolling. | Structual members .etc.kitchen utensil ,cutlery ,eleltric applicances ,medical instruments ,building decorations ,etc. | |

| NO.3/NO.4 | Polished with No.150-240 abrasives. | Milky food processing equipment , medicalinstruments ,building decorations. | |

| HL | Finshed by polishing with abrasives of suitable grain size to obtain continuous streaks. | Building decorations ,such as elevators ,escalators ,door etc. | |

| 6K/8K | A mirror-like reflective surface ,which is obtained by polishing with successively finer abrasives and buffing extensively with all gritlines are removed. | Buliding entrances,bulkding column casting ,elevator's wall doors ,counters,sculptures etc. | |

MECHANICAL PROPERTIES

CHEMICAL COMPOSITION AND MECHANICAL PROPERTIES OF STAINLESS STEEL CIRCLE

| Grade | Chemical Composition (%) | Mechanieal Performece | |||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | Hardness | |

| 201 | ≤0.15 | ≤1.00 | 5.5/7.5 | ≤0.060 | ≤0.030 | 3.5/5.5 | 16.0/18.0 | - | HB≤241,HRB≤100, HV≤240 |

| 304 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 8.0/11.0 | 18.00/20.00 | - | HB≤187,HRB≤90,HV≤200 |

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 10.00/14.00 | 16.0/18.0 | 2.00/3.00 | HB≤187, HRB≤90 HV≤200 |

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 10.00/14.00 | 16.0/18.0 | 2.00/3.00 | HB≤187, HRB≤90 HV≤200 |

| 410 | ≤0.15 | ≤1.00 | ≤1.25 | ≤0.060 | ≤0.030 | ≤0.060 | 11.5/13.5 | - | HB≤183, HRB≤88 HV≤200 |

| 430 | ≤0.12 | ≤1.00 | ≤1.25 | ≤0.040 | ≤0.03 | - | 16.00/18.00 | - | HB≤183, HRB≤88 HV≤200 |

APPLICATION

Cooking Utensils ,

Lamps ,

Cylinders ,

Steel Sans ,

Tank Head