| Availability: | |

|---|---|

| Quantity: | |

PRODUCT DESCRIPTION

STAINLESS STEEL ROUND PLATE | PUXIN METAL

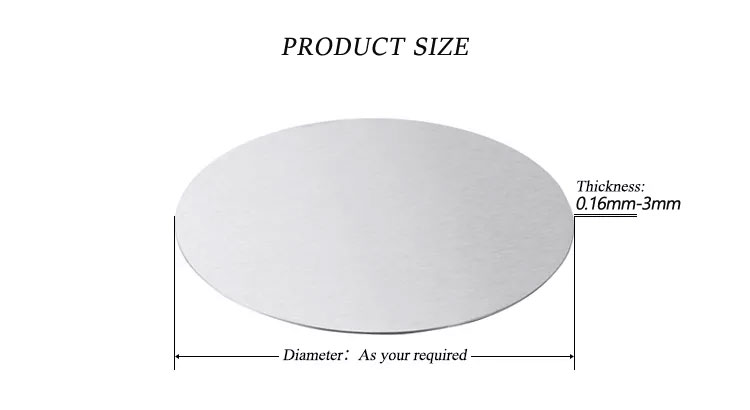

size:Support customization

Standard:ASTM ;AISI;JIS;UNS;EN

Grade:201/304/316L/317/310S/321/2205/430/441/443

Surface: NO. 1, 2B, BA, NO. 3, NO. 4, HL

MOQ : 5 TONThe stainless steel round plate is pressed by determining the circular shape and size mold to be made, placing the stainless steel plate in the mold, and applying a certain pressure with a press or punch to press the stainless steel plate into the required circular plate. The stainless steel round plate is then processed and polished. Stainless steel round plates are very suitable for indoor and outdoor use and will not rust due to the corrosion resistance of stainless steel.

PRODUCT PERFORMANCE

STAINLESS STEEL. WILL NOT RUST.

SURFACE FINE GRINDING.

CAN BE USED FOR TABLEWARE AND FOOD GRADE.

CAN BE STAMPED INTO DESIRED SHAPES

CAN BE CUT TO DESIRED SIZE BY MACHINE

CORROSION RESISTANCE,

HIGH TEMPERATURE RESISTANCE,

LOW TEMPERATURE RESISTANCE.

NOTE: This sheet is not magnetic. Click here to order magnetic sheets

PRODUCT SHOW

PRODUCT ADVANTAGES

CHEMICAL COMPOSITION

Grade | C | Mn | P | S | Si | Cr | Ni |

201 | ≤0.15 | 5.5~7.5 | ≤0.050 | ≤0.03 | ≤1.00 | 16.0~18.0 | 3.5~5.5 |

202 | ≤0.15 | 7.5~10 | ≤0.060 | ≤0.03 | ≤1.00 | 17.0~19.0 | 4.0~6.0 |

301 | ≤0.15 | ≤2.00 | ≤0.045 | ≤0.03 | ≤1.00 | 16.5~18.0 | 6.0~8.0 |

302 | ≤0.15 | ≤2.00 | ≤0.045 | ≤0.03 | ≤1.00 | 17.0~19.0 | 8.0~10.0 |

304 | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤1.00 | 18.0~20.0 | 8.0~10.5 |

304L | ≤0.03 | ≤2.00 | ≤0.045 | ≤0.03 | ≤1.00 | 18.0~20.0 | 8.0~12.0 |

308 | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤1.00 | 18.0~21.0 | 10.0~12.0 |

310S | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤1.00 | 24.0~26.0 | 19.0~22.0 |

| Surface finish | Definition | Application |

| 2B | Those finishedafter cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipmentFood industry Construction materialKitchen utensils. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils,Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils,Building construction,Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction |

| BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils,Electric equipment,Building construction. |

SURFACE TREATMENT

APPLICATION