| Availability: | |

|---|---|

| Quantity: | |

PRODUCT DESCRIPTION

PRODUCT SPECIFICATION

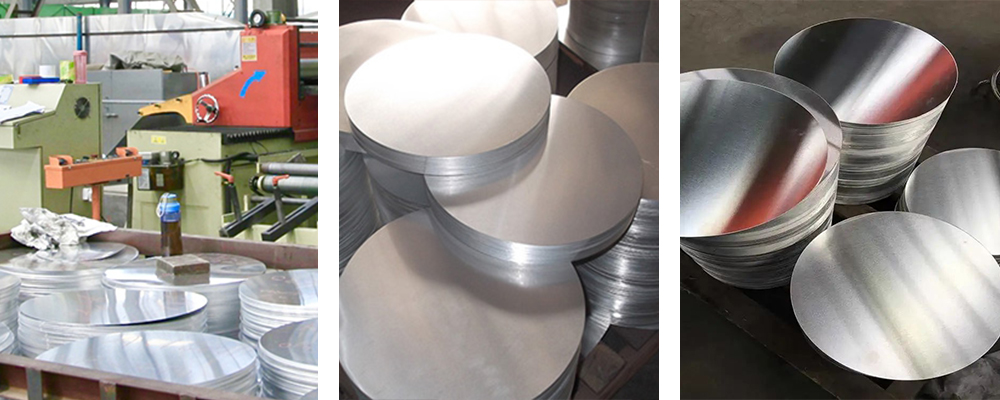

3-PLY TRIPLY CIRCLE STAINLESS STEEL WOK/FRYPAN/SAUCEPAN/CASSEROLE | PUXIN METAL

size: We offer custom sizes and thicknesses tailored to your specific needs

Material:304SS + Aluminum + 430SS;304SS + Aluminum + 304SS;304SS + Aluminum + Copper;Aluminum + SS430 + Copper

Standard:ASTM ;AISI;JIS;UNS;EN

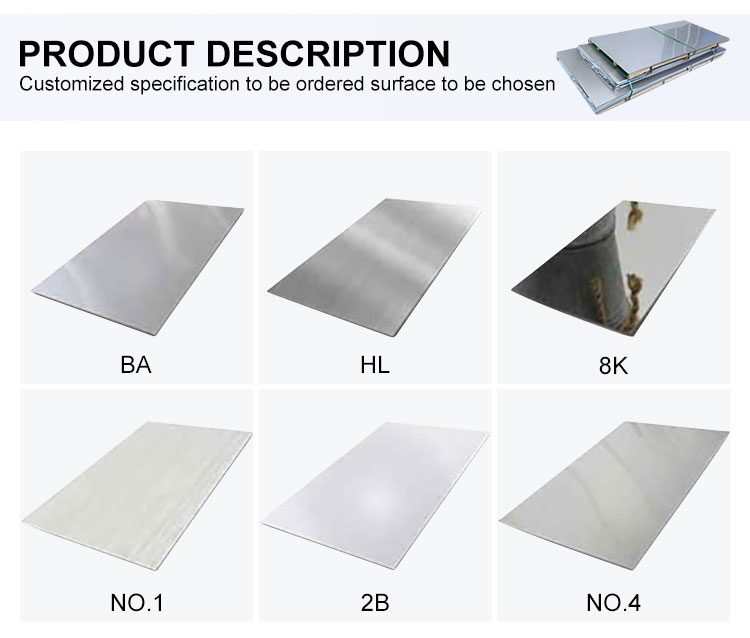

Surface: 2B;BA;NO.1;HL;8K

MOQ : 5 TON

Stock:Enough

Use:Automobile Industry;Construction;Cookware;

3ply Triply Circle China manufacturers, suppliers, factory, wholesale

IF YOU NEED OTHER SIZES, PLEASE CONTACT US FOR MORE INFORMATION.

Triply/5-ply circles are specially designed for optimal conductivity and heat distribution during cooking. These circles are made by compressing three or five different metals together using advanced technology, resulting in a highly efficient cooking surface. The circles are then cut into blanks for use in high-quality cookware. With their superior heat conductivity, these circles ensure even cooking and consistent results every time. Upgrade your kitchen with cookware featuring triply/5-ply circles for a professional cooking experience.

| Type | Thickness (mm) | Combination (s) | Diameters |

| Three-ply | 2 – 3.1mm | 304 + Alu + 430 | 200 – 500mm |

| Five-Ply | 2 – 3.1mm | 304 + Alu + Cu + Al + 430 / 430 + Alu + Cu + Alu + 430 | 200 – 500mm |

| We offer custom sizes and thicknesses tailored to your specific needs | |||

PRODUCT FEATURES

PRODUCT CHARACTERISTICS OF 3PLY TRIPLY CIRCLE

Three-layer composite metal, performance upgrade

304/316L/430 stainless steel (outer layer) - provides excellent corrosion resistance and high temperature resistance, ensures food contact safety, and is suitable for induction cooker heating.

Aluminum/Copper (middle layer) - excellent thermal conductivity, achieves uniform heating, improves thermal efficiency, and reduces energy loss.

430 stainless steel (bottom layer, optional) - suitable for induction heating of induction cookers, improves heating speed and energy saving effect.

High thermal conductivity, high efficiency, energy saving and environmental protection

The thermal conductivity of the composite aluminum core is as high as 160 W/m·K, which is more than 5 times that of traditional stainless steel, significantly reducing cooking heating time and saving more than 30% energy.

The copper core solution provides faster thermal response and is suitable for high-end professional cookware and industrial heat-conducting components.

High strength and durability

Explosive welding or high temperature rolling combined technology makes the metal layers tightly bonded, not easy to delaminate or peel off, suitable for high-strength processing such as deep drawing, stretching, and stamping.

High temperature resistance up to 400°C, can be used for a long time without deformation or discoloration.

Environmentally friendly and healthy, in line with international food grade standards

SURFACE TREATMENT

APPLICATION

✅ High-end cookware manufacturing - Suitable for composite pot bottom materials such as non-stick pans, frying pans, soup pots, steamers, pressure cookers, etc., supporting OEM / ODM customization.

✅ Kitchen appliances - Suitable for high thermal conductivity components such as induction cookers, baking trays, and electric kettle heating chassis.

✅ Precision machinery manufacturing - Suitable for high-intensity applications such as deep stamping, precision machining, and mold manufacturing.

✅ Medical equipment & scientific research equipment - Suitable for medical instrument components with corrosion resistance, high strength, and high thermal conductivity requirements.

✅ New energy industry - Suitable for high-tech products such as thermal energy conversion equipment, heat sinks, and electronic thermal conductive plates.

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | N | Other | |

| 201 | 0.15 | 1 | 5.5-7.5 | 0.06 | 0.03 | 3.5-5.5 | 16-18 | - | - | 0.25 | |

| 202 | 0.15 | 1 | 7.5-10 | 0.05 | 0.03 | 1 | 17-19 | - | - | 0.05-0.25 | |

| 301 | 0.15 | 1 | 2 | 0.045 | 0.03 | 6-8 | 16-18 | - | - | 0.1 | |

| 304 | 0.08 | 1 | 2 | 0.045 | 0.03 | 8-11 | 18-20 | - | - | - | |

| 304L | 0.03 | 1 | 2 | 0.045 | 0.03 | 8-12 | 18-20 | - | - | - | |

| 309S | 0.08 | 1 | 2 | 0.045 | 0.03 | 12-15 | 22-24 | - | - | - | |

| 310 | 0.25 | 1.5 | 2 | 0.045 | 0.03 | 19-22 | 24-26 | - | - | - | |

| 310S | 0.08 | 1 | 2 | 0.045 | 0.03 | 19-22 | 24-26 | - | - | - | |

| 316 | 0.08 | 1 | 2 | 0.045 | 0.03 | 10-14 | 16-18 | 2-3 | - | - | |

| 316L | 0.03 | 1 | 2 | 0.045 | 0.03 | 10-14 | 16-18 | 2-3 | - | - | |

| 316Ti | 0.08 | 1 | 2 | 0.045 | 0.03 | 10-14 | 16-18 | 2-3 | 0.1 | Ti≥5C | |

| 317L | 0.03 | 1 | 2 | 0.045 | 0.03 | 11-15 | 18-20 | 3-4 | - | - | |

| 321 | 0.08 | 1 | 2 | 0.045 | 0.03 | 9-12 | 17-19 | - | - | Ti:5c-0.70 | |

| 430 | 0.12 | 1 | 1 | 0.04 | 0.03 | - | - | ||||

| 904L | 0.02 | 1 | 2 | 0.04 | 0.03 | 23-28 | 19-23 | 4-5 | 1-2 | 0.1 | |

| 2205 | 0.03 | 1 | 2 | 0.03 | 0.02 | 4.5-6.5 | 22-23 | 3-3.5 | - | 0.14-0.2 | |

| 254SMO | 0.02 | 0.8 | 1 | 0.03 | 0.01 | 17.5-18.5 | 19.5-20.5 | 6.0-6.5 | - | 0.18-0.25 | |

| 654SMO | 0.02 | 0.5 | 2-4 | 0.03 | 0.005 | 21-25 | 24-25 | 0.3-0.6 | 7-8 | 0.45-0.55 | |

| 253MA | 0.05-0.1 | 1.4-2 | 0.8 | 0.04 | 0.03 | 10-12 | 20-22 | - | - | 0.14-0.2 | ce:0.03-0.08 |

| AL-6XN | 0.03 | 1 | 2 | 0.04 | 0.03 | 23.5-25.5 | 20-22 | 6-7 | 0.75 | 0.18-0.25 | |

| S32750 | 0.03 | 0.8 | 1.2 | 0.035 | 0.02 | 6-8 | 24-26 | 3-5 | 0.5 | 0.24-0.32 | |

| S32760 | 0.03 | 1 | 1 | 0.03 | 0.01 | 6-8 | 24-26 | 3-4 | 0.5-1 | 0.2-0.3 |