| Availability: | |

|---|---|

| Quantity: | |

PRODUCT DESCRIPTION

AISI 440B STAINLESS STEEL SHEET / PLATE FOR SALE

Grade:85Cr17;S44080;440B;SUS 440B;STS 440B;440B;S44003

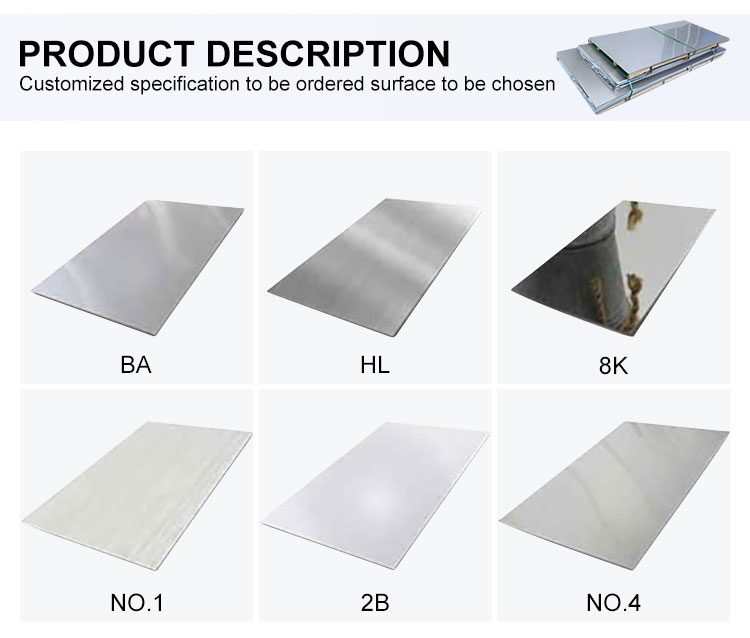

Surface: NO. 1, 2B, BA, NO. 3, NO. 4, HL

MOQ : 5 TON”CHOOSE PUXIN STEEL AND LOOK FORWARD TO HEARING FROM YOU!“

440B stainless steel is a high-quality martensitic stainless steel with high hardness and excellent wear resistance. It is widely used in cutting tools, measuring tools, bearings and other fields that require high strength and wear resistance. Compared with SUS440A, 440B has higher hardness; compared with SUS440C, it has better toughness. During the processing, although it heats up quickly and has greater viscosity, its grinding and cutting performance is superior to carbon steel. Suitable for applications that require high hardness and good wear resistance, such as mechanical parts such as cutting tools and bearings.

PRODUCT PERFORMANCE

Features of AISI 440B stainless steel plate

High toughness

Corrosion resistance

High hardness

PRODUCT FEATURES

PRODUCT CHARACTERISTICS OF 440B STAINLESS STEEL PLATE

440A steel and 440B steel have higher hardness; compared with 440C steel, 440B has better toughness.

It is especially suitable for making bayonet blades in the fields of cutting tools, measuring tools, bearings, valves, etc.

440B steel has excellent wear resistance and is suitable for use in high-load and high-wear environments. It can maintain a higher working life to a certain extent.

PRODUCT PARAMETERS

PRODUCT PARAMETERS

Carbon C: 0.85~0.95,

Silicon Si: ≤1.00,

Manganese Mn: ≤1.00,

Sulfur S: ≤0.030,

Phosphorus P: ≤0.035,

Chromium Cr: 16.00~18.00,

Nickel Ni is allowed to contain: ≤0.60,

Molybdenum Mo can be added: ≤0.75

Annealing/℃: 800~920 slow cooling

Quenching/℃: 1010~1070 oil cooling

Tempering/℃: 100~180 fast cooling

Hardness value after annealing HBS≤255;HBR≥56

So it is magnetic. Under normal circumstances (in air), 440B will not rust. Uses: 440B stainless steel is used for cutting tools, measuring tools, bearings, and valves. Suitable for making bayonet blades. Performance: 440B stainless steel is harder than 440A steel and tougher than 440C steel.

SURFACE TREATMENT

PUXIN STEEL offers 440B stainless steel plates in a variety of thicknesses and sizes, ranging from 0.3mm to 6.0mm. We also provide customized cutting and surface processing services, including options such as mirror, brushed, and sandblasting finishes, to meet the specific needs of our customers.

APPLICATION

Cutting tools, measuring tools

Tableware, valve parts

Instrument bearings