| Availability: | |

|---|---|

| Quantity: | |

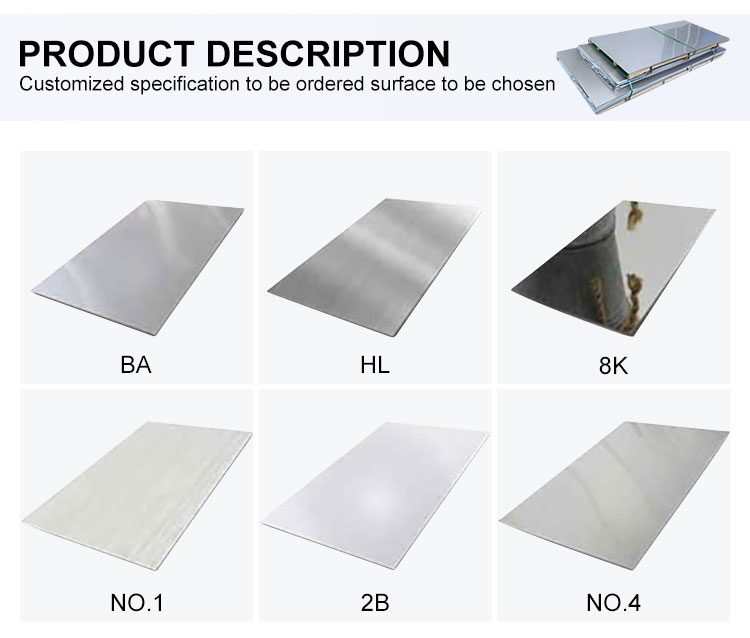

PRODUCT DESCRIPTION

AISI 304 STAINLESS STEEL SHEET| PUXIN METAL

Thickness: HR(2.5.0MM~14.0MM);CR(0.18MM~3.0MM)

Width: 10MM~1800MM

Grade:06Cr19Ni9;SUS 304;ASTM 304;S30400;X5CrNi 18-10;1.4301;08X18H10;2332

Standard:GB/T4238、ASTM/ASME、 JIS G4305、EN10088、BSEN10028、GB/T3280、GB/T4237

Surface: NO.1、2B、2D、3#、4#、HL、BA

Technique: Hot Rolled & Cold Rolled

Payment terms: L/C T/T (30%DEPOSIT)

Capacity:Monthly shipment volume reaches 4000+ tons

Processing Service:Bending, Welding, Decoiling, Punching, Cutting.

USE:Machined parts, pump shafts, bolts, bushings, coal chutes, cutlery, hardware, jet engine parts, mining machinery, gun barrels, screws and valves.

Compared with 304L Stainless steel

304L has better corrosion resistance and lower carbon content.

304 has a wide range of uses and has good corrosion resistance, heat resistance, low temperature strength and mechanical properties; good thermal processing properties, such as stamping and bending, without heat treatment and hardening phenomena (non-magnetic, use temperature -196°C~ 800°C).

304L has excellent resistance to grain boundary corrosion after welding or stress relief; it can also maintain good corrosion resistance without heat treatment, and the service temperature is-196°C-800°C.

According to the manufacturing method, stainless steel plates are divided into two types: hot-rolled and cold-rolled. According to the structural characteristics of the steel, they are divided into five types: austenite, austenite-ferrite, ferrite, martensite and precipitation hardening. kind. It needs to withstand the corrosion of various acids, such as oxalic acid, sulfuric acid-ferrous sulfate, nitric acid, nitric acid-hydrofluoric acid, sulfuric acid-copper sulfate, phosphoric acid, formic acid, acetic acid, etc. It is widely used in chemical, food, pharmaceutical, papermaking, petroleum, atomic energy and other industries, as well as various parts and components such as construction, kitchen utensils, tableware, vehicles, and home appliances.

Stainless steel plates have smooth surfaces, high plasticity, toughness and mechanical strength, and can resist corrosion from acids, alkaline gases, solutions and other media. It is an alloy steel that is not prone to rust, but it is not absolutely rust-free.

Stainless steel plates are divided into hot rolling and cold rolling according to the manufacturing method, including thin cold plates with a thickness of 0.02-4mm and medium and thick plates with a thickness of 4.5-100mm.

In order to ensure that the mechanical properties such as yield strength, tensile strength, elongation and hardness of various stainless steel plates meet the requirements, the steel plates must undergo heat treatment processes such as annealing, solution treatment, and aging treatment before delivery.

The corrosion resistance of stainless steel mainly depends on its alloy composition (chromium, nickel, titanium, silicon, aluminum, etc.) and internal structure, among which chromium plays a major role. Chromium has high chemical stability and can form a passivation film on the surface of steel to isolate the metal from contact with the outside world, protect the steel plate from oxidation, and increase the corrosion resistance of the steel plate. After the passivation film is destroyed, the corrosion resistance will be reduced.

304 stainless steel plate has beautiful surface and diverse usage possibilities

Good corrosion resistance, longer lasting than ordinary steel

High strength, so thin plates can be used

High temperature oxidation resistance and high strength, so it can resist fire

Processing at room temperature, that is, easy plastic processing

Since no surface treatment is required, it is simple and easy to maintain

Clean and smooth

Good welding performance.

ASTM 304 Stainless steel coils,304 stainless steel pipe

PHYSICAL PROPERTIES

(304)06CR19NI10 CHEMICAL ELEMENT CONTENT (%)

| Element | Composition (%) |

| Carbon (C) | 0.08 |

| Silicon (Si) | 1.00 |

| Manganese (Mn) | 2.00 |

| Chromium (Cr) | 16~18.50 |

| Nickel(Ni) | 8~11 |

| Sulfur(S) | 0.030 |

| Phosphorus(P) | 0.045 |

| ASTM | TS(Mpa)≥ | YS(Mpa)≥ | EL(%)≥ | Hardness | |

| HB | HRB | ||||

| 201 | 520 | 275 | 40 | 241 | 100 |

| 202 | 520 | 275 | 40 | 207 | 95 |

| 301 | 520 | 205 | 40 | 207 | 95 |

| 304 | 520 | 205 | 40 | 20 | 90 |

| 304L | 480 | 175 | 40 | 187 | 90 |

| 309S | 520 | 205 | 40 | 187 | 90 |

| 310 | 520 | 205 | 40 | 187 | 90 |

| 310S | 520 | 205 | 40 | 187 | 90 |

| 316 | 520 | 205 | 40 | 187 | 90 |

| 316L | 480 | 175 | 40 | 187 | 90 |

| 316Ti | 520 | 205 | 40 | 187 | 90 |

| 317L | 480 | 175 | 40 | 187 | 90 |

| 321 | 520 | 205 | 40 | 187 | 90 |

| 430 | 450 | 205 | 22 | 183 | 88 |

| 904L | 490 | 216 | 35 | ||

| 2205 | 640 | 25 | |||

SURFACE FINISH

| 2B | After treatment, the final light cold rolling is carried out through the polishing roller to obtain the proper gloss. | |||||||

| Grade | Thickness | |||||||

| 201 | 0.3-16.0 | |||||||

| 304/304L | 0.3-16.0 | |||||||

| 316/316L | 0.3-16.0 | |||||||

| 309(S) | 0.3-16.0 | |||||||

| 310(S) | 0.3-16.0 | |||||||

| 321 | 0.3-16.0 | |||||||

| 410 | 0.3-16.0 | |||||||

| 430 | 0.3-16.0 | |||||||

| 9041 | 0.3-16.0 | |||||||

| 2205 | 0.3-16.0 | |||||||

| BA | Bright as mirror no standard,but usually bright annealing surface processing, high surface reflection.Building materials, kitchen utensils | |||||||

| Grade | Thickness | |||||||

| 201 | 0.3-16.0 | |||||||

| 304/304L | 0.3-16.0 | |||||||

| 316/316L | 0.3-16.0 | |||||||

| 309(S) | 0.3-16.0 | |||||||

| 310(S) | 0.3-16.0 | |||||||

| 321 | 0.3-16.0 | |||||||

ADVANTAGE

The stainless steel plate has a smooth surface, high plasticity, toughness and mechanical strength, and is resistant to corrosion by acids, alkaline gases, solutions and other media. It is an alloy steel that is not easy to rust, but it is not absolutely rust-free.

Corrosion resistance

Stainless steel plates have a similar ability to resist general corrosion as unstable nickel-chromium alloy 304. Prolonged heating in the temperature range of chromium carbide levels may affect alloys 321 and 347 in harsh corrosive media. Mainly used for high temperature applications, which require materials with strong resistance to sensitization to prevent intergranular corrosion at lower temperatures.

High temperature oxidation resistance

Stainless steel plates all have high-temperature oxidation resistance, but the oxidation rate will be affected by inherent factors such as exposure environment and product form.

If you are interested in this product, you can also take a look at our other products, our company also produces a variety of stainless steel products, such as stainless steel pipe, stainless steel coil and so on.

Why Choose Us?

Top 20 companies in steel industry trade volume.

Customized processing steel one-stop purchase.

We have a complete set of testing equipment.

We have our own stainless steel manufacturing factory.