| Availability: | |

|---|---|

| Quantity: | |

PRODUCT DESCRIPTION

STAINLESS STEEL SHEET WITH WOOD PATTERN FOR SALE

Grade:AISI 201;AISI 304;AISI 316

Surface: Wood Grain

MOQ : 1 TON”CHOOSE PUXIN METAL AND LOOK FORWARD TO HEARING FROM YOU!“

Wood pattern stainless steel laminate sheets are an innovative decorative material that seamlessly blends the natural aesthetic of wood with the exceptional durability and corrosion resistance of stainless steel. Ideal for both interior design and architectural applications, these sheets provide an authentic wood-like appearance while delivering the robust performance of stainless steel.This versatile material is a practical and stylish solution for environments where traditional wood may be unsuitable due to maintenance challenges or specific performance demands. By combining the timeless beauty of wood with the functional advantages of stainless steel, these laminate sheets offer a unique and sophisticated option for enhancing modern design and architectural projects.

PRODUCT PERFORMANCE

Features of stainless steel plate with wood pattern

Laminated stainless steel sheets are bright in color,

can be designed in a variety of colors and patterns,

customizable wood grain series and marble series are popular with customers.

Waterproof, fireproof, and with excellent durability

Weather resistance, corrosion resistance, chemical resistance

Strong anti-fouling ability.

Laminates of different materials and thicknesses have different applications

PRODUCT SHOW

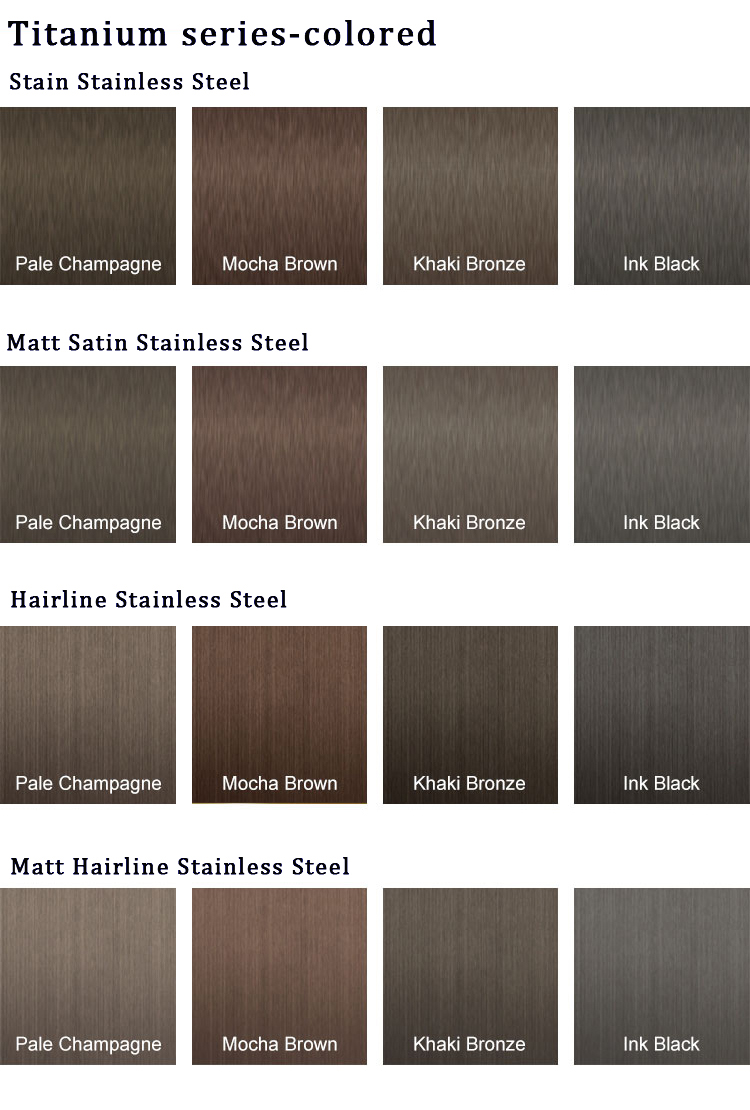

SURFACE TREATMENT

APPLICATION

Wood grain stainless steel laminate sheet adopts innovative surface treatment technology, and can be customized with a variety of wood grains, marble textures and high-precision color reproduction finishes, combining the strength of metal substrates with the visual beauty of natural materials. With its ultra-thin thickness of 0.8-3.0mm, corrosion resistance, and easy cleaning, this product has become an ideal solution for high-end commercial spaces (hotels/shopping malls/exhibition halls), modern home kitchen systems, and building curtain wall decoration, meeting the fire protection A1 standard and sustainable environmental protection requirements.

If you are interested in this product, you can also take a look at our other products, our company also produces a variety of stainless steel products, such as stainless steel pipe, stainless steel coil and so on.