AISI 309 STAINLESS STEEL COILS SUPPLIER | PUXIN METAL

Thickness: HR:2.5MM~14MM;CR:0.18MM~3.0MM| Availability: | |

|---|---|

| Quantity: | |

PRODUCT DESCRIPTION

AISI 309 STAINLESS STEEL COILS | PUXIN METAL

HR Thickness:2.5MM~14MM

CR Thickness:0.18MM~3.0MM

Width: 1000MM;1219MM;1500MM;1800MM;

Length: 1000MM~8000MM;As required

Shape: ROLL

Technique: Hot Rolled/Cold Rolled

Type:Austenitic stainless steel

Surface Treatment : 2B/BA/NO.1/8K/HL/NO.4

MOQ:5 TON

Samples:Support

Stock:Standing inventory of 10,000+ tons

Payment terms: L/C T/T (30%DEPOSIT)

Capacity:Monthly shipment volume reaches 4000+ tons

Processing Service:Bending, Welding, Decoiling, Punching, Cutting.

309 stainless steel coils have become the core material of choice for boiler manufacturing, chemical equipment and high-temperature piping systems due to their excellent high-temperature tolerance and corrosion resistance. As a typical representative of high-alloy austenitic stainless steel, this material builds a double protective barrier with a chromium content of 19%-23% and a nickel content of 12%-15%. It can still form a dense chromium oxide protective layer in a high-temperature environment of 800℃, effectively blocking oxidation corrosion and medium penetration. Compared with traditional 0Cr19Ni9 stainless steel, the synergistic effect of trace elements such as molybdenum and titanium increases the resistance to chloride stress corrosion by 30%, and the thermal strength is significantly enhanced. It can be used stably in harsh working conditions such as heat exchangers and cracking units for a long time.

Through 1050-1150℃ solution heat treatment and rapid water cooling process, 309 stainless steel coils obtain uniform single-phase austenitic metallographic structure, showing excellent cold working plasticity and welding formability, and supporting the precision processing of complex structural parts. 309 Stainless steel material performs outstandingly in nitric acid concentration equipment, high-temperature furnace manufacturing and strong acid medium transportation pipelines. It has both intergranular corrosion resistance and carburization resistance. Its service life is 2-3 times longer than that of conventional stainless steel, providing lasting guarantee for the long-term and stable operation of equipment in the fields of energy, petrochemicals, environmental protection, etc.

High temperature equipment,

Pipes,

Electrical industry,

Medical equipment, Construction,

Chemical,

Food industry,

Agriculture and ship parts,

Food and beverage packaging,

Kitchen supplies,

Trains,

Aircraft,

Conveyor belts,

Vehicles,

Bolts,

Nuts,

Springs and screens, etc.

PRODUCT DETAILS

309 STAINLESS STEEL CHEMICAL COMPOSITION

Element | Composition (%) |

Carbon (C) | 0.2 |

Silicon (Si) | 1.00 |

Manganese (Mn) | 2.00 |

Chromium(Cr) | 22~24 |

Nickel(Ni) | 12.0~15.0 |

Sulfur(S) | 0.03 |

Phosphorus(P) | 0.045 |

CHEMICAL COMPOSITION

Yield Strength (Mpa) | ≥205 |

Tensile strength (Mpa) | ≥520 |

Elongation (%) | ≥ 60 |

Hardness | HBW ≤269 HRB ≤ 90 |

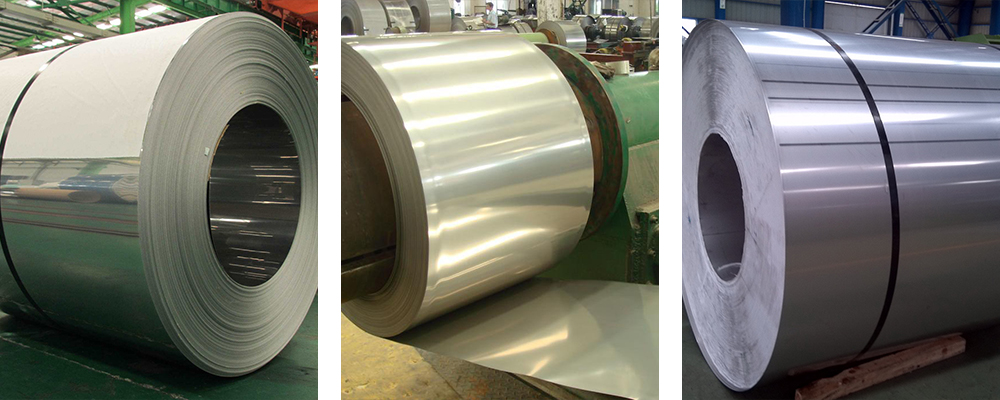

PRODUCT SHOW