| Availability: | |

|---|---|

| Quantity: | |

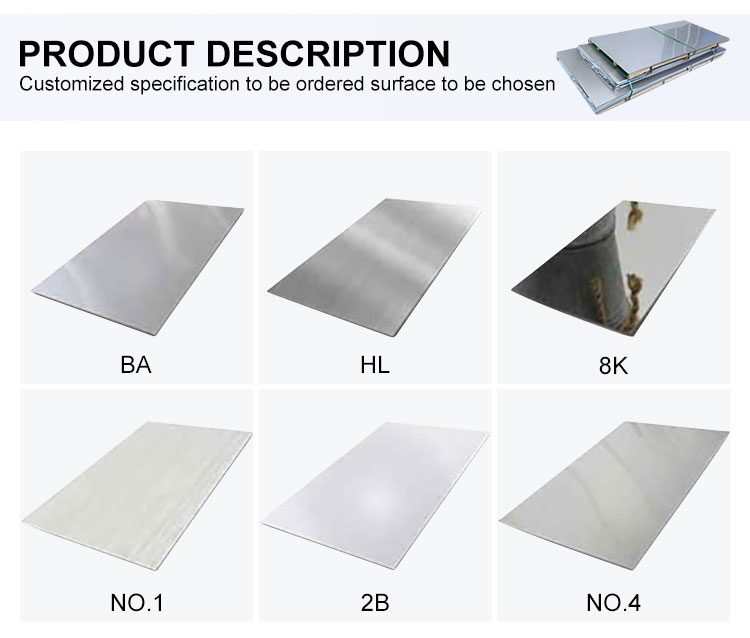

PRODUCT DESCRIPTION

AISI 303 STAINLESS STEEL SHEET / PLATE FOR SALE

Grade:Y1Cr18Ni9;SUS 303;ASTM 303;S30300;X10CrNiS 18-9;1.4305

Surface: NO. 1, 2B, BA, NO. 3, NO. 4, HL

MOQ : 5 TON”CHOOSE PUXIN STEEL AND LOOK FORWARD TO HEARING FROM YOU!“

AISI 303 stainless steel plate is widely used in petroleum, electronics, chemical, pharmaceutical, textile, food, machinery, construction, nuclear power, aerospace, military and other industries. Our company has ISO9001:2000 quality management system certification and production license to ensure reliable product quality.

PRODUCT PERFORMANCE

Features of 303 stainless steel plate

Excellent cutting performance

High temperature resistance

Strong corrosion resistance

PRODUCT FEATURES

PRODUCT CHARACTERISTICS OF 303 STAINLESS STEEL PLATE

AISI 303 stainless steel plate is a free-cutting stainless steel containing sulfur and selenium, with excellent cutting performance and high temperature bonding resistance. It is particularly suitable for automatic lathe processing and is often used to manufacture products such as bolts and nuts. In order to improve the performance of 303 stainless steel, no more than 0.60% of molybdenum can be added to the steel to improve the ablation resistance and corrosion resistance. After annealing and stress relief treatment, the mechanical properties of AISI 303 stainless steel are excellent, with a tensile strength of 515MPa, a yield strength of 205MPa, and an elongation of 40%. The standard hardness is HRB 90-100 and HRC 20-25.

PRODUCT PARAMETERS

PRODUCT PARAMETERS

| ELEMENT(%) | |

| C | ≤0.15 |

| Si | ≤1.00 |

| Mn | ≤2.00 |

| P | ≤0.20 |

| S | ≤0.15 |

| Ni | 8.00~10.00 |

| Cr | 17.00~19.00 |

PHYSICAL PARAMETERS OF 303 STAINLESS STEEL PLATE

Tensile strength σb (MPa): ≥520

Conditional yield strength σ0.2 (MPa): ≥205

Elongation δ5 (%): ≥40

Sectional shrinkage ψ (%): ≥50

Hardness: ≤187HB; ≤90HRB; ≤200H

SURFACE TREATMENT

PUXIN STEEL offers 303 stainless steel plates in a variety of thicknesses and sizes, ranging from 0.3mm to 6.0mm. We also provide customized cutting and surface processing services, including options such as mirror, brushed, and sandblasting finishes, to meet the specific needs of our customers.

APPLICATION

High-pressure equipment and accessories such as pipes and valves.

Electronic components and connectors.

Chemical equipment and reaction vessels

Medical equipment, pharmaceutical production equipment

Mechanical parts and equipment.

Food processing equipment and packaging equipment

Automatic lathe processing parts, such as bolts, nuts, etc.

Structural steel, steel in bridges and other construction projects.

Nuclear power equipment and facilities

Aerospace equipment and components

Military equipment manufacturing