AISI 201 STAINLESS STEEL COILS FOR SALE | PUXIN METAL

Thickness: 0.03MM-5.0MM| Availability: | |

|---|---|

| Quantity: | |

PRODUCT DESCRIPTION

AISI 201 STAINLESS STEEL COILS| PUXIN METAL

Thickness:0.02MM-2.5MM

Width: 3.5MM-1550MM

Length: As required

Shape: Roll

Technique: Hot Rolled/Cold Rolled

Type:Martensitic stainless steel

Surface Treatment : BA、2B、NO.1、2D、NO.4、HL、8K

MOQ:5 TON

Samples:Support

Stock:Standing inventory of 10,000+ tons

Payment terms: L/C T/T (30%DEPOSIT)

Capacity: 4000+ tons

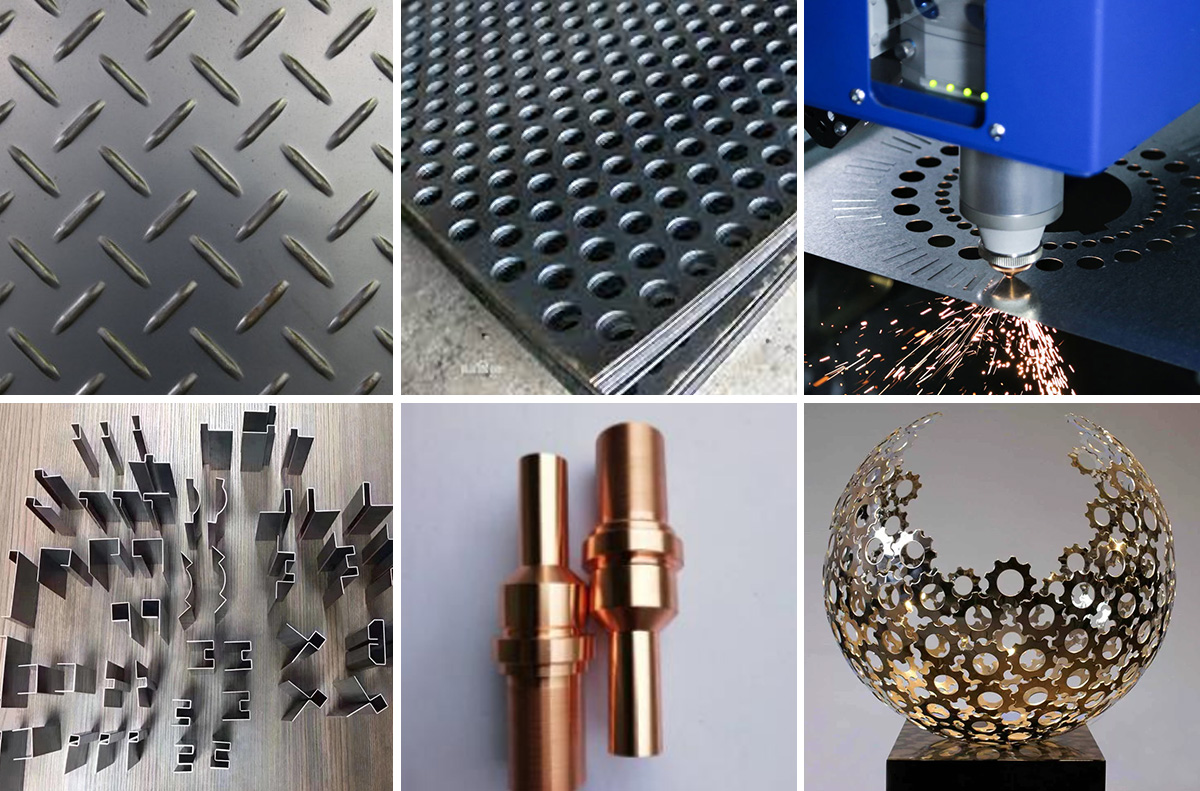

Processing Service:Bending, Welding, Decoiling, Punching, Cutting.

USE:Manufacture of cutlery, automobile wheel covers and wheel covers,Decorative ss pipes, industrial stainless pipes.

AISI 201 stainless steel coil is a commonly used stainless steel material with certain acid and alkali resistance, high density, polishing without bubbles and pinholes. It has a high manganese content and a low nickel content, and the surface is bright but easy to rust. 201 stainless steel coil is a high-quality material for producing various watch cases, watch strap bottom covers, etc. It can also be used to make decorative pipes, industrial pipes and some shallow-drawn products. It is widely used in construction, kitchenware, automobile manufacturing and other fields.

Acid and alkali resistant

Easy to process

Widely used

Affordable price

Element | Composition (%) |

Carbon (C) | 0.15 |

Silicon (Si) | 0.75 |

Manganese (Mn) | 5.5~7.5 |

Chromium(Cr) | 16.0~18.0 |

Nickel(Ni) | 3.3~3.5 |

Sulfur(S) | 0.030 |

Phosphorus(P) | 0.060 |

MECHANICAL PROPERTY

Tensile strength: 520MPa

Yield strength: 275MPa

Elongation: 55 to 60%

Elastic modulus: 29,000,000 psi equivalent to: 203000MPa

Hardness requirement (Rockwell hardness) HRB≤100.

Density: .280lbs/cubic inch (density 7.93g/cm3)

PRODUCT SHOW

TECHNOLOGY

FACTORY

201 STAINLESS STEEL DENSITY

GRADE | Density (*103 kg/m3) | GRADE | Density (*103 kg/m3) |

00Cr30Mo2 | 7.64 | 00Cr19Ni13Mo3 | 7.98 |

00Cr27Mo | 7.67 | 0Cr19Ni12Mo3 | 7.98 |

1Cr17Mo | 7.70 | 0Cr25Ni20 | 7.98 |

1Cr15 | 7.70 | 0Cr18Ni12Mo2Cu2 | 7.98 |

3Cr16 | 7.70 | 00Cr18Ni14Mo2Cu2 | 7.98 |

00Cr27Mo | 7.67 | 0Cr19Ni12Mo3 | 7.98 |

1Cr17 | 7.70 | 00Cr19Ni13Mo3 | 7.98 |

00Cr17 | 7.70 | 0Cr18Ni11Nb | 7.98 |

7Cr17 | 7.70 | 0Cr17Ni12Mo2N | 7.98 |

1Cr12 | 7.76 | 00Cr17Ni14Mo2 | 7.98 |

1Cr13 | 7.76 | 0Cr17Ni12Mo2N | 7.98 |

0Cr13Ai | 7.75 | 00Cr17Ni13Mo2N | 7.98 |

00Cr12 | 7.76 | 0Cr18Ni16Mo5 | 8.00 |

0Cr13Al | 7.75 | 1Cr17Ni7 | 7.93 |

2Cr13 | 7.75 | 0Cr23Ni13 | 7.93 |

3Cr13 | 7.75 | 1Cr17Ni8 | 7.93 |

0Cr18Ni13Si4 | 7.75 | 1Cr18Ni9 | 7.93 |

00Cr18Mo2 | 7.75 | 1Cr18Ni9Si3 | 7.93 |

0Cr26Ni5Mo2 | 7.80 | 0Cr19Ni9 | 7.93 |

1Cr17Mn6Ni5N | 7.93 | 00Cr19Ni11 | 7.93 |

00Cr18Ni9S13 | 7.93 | 0Cr19Ni9N | 7.93 |

1Cr17Mn6Ni6N | 7.93 | 0Cr18Ni11Ti | 7.93 |

1Cr18nNi8Ni5N | 7.93 | 0Cr17Ni17Al | 7.93 |