| Availability: | |

|---|---|

| Quantity: | |

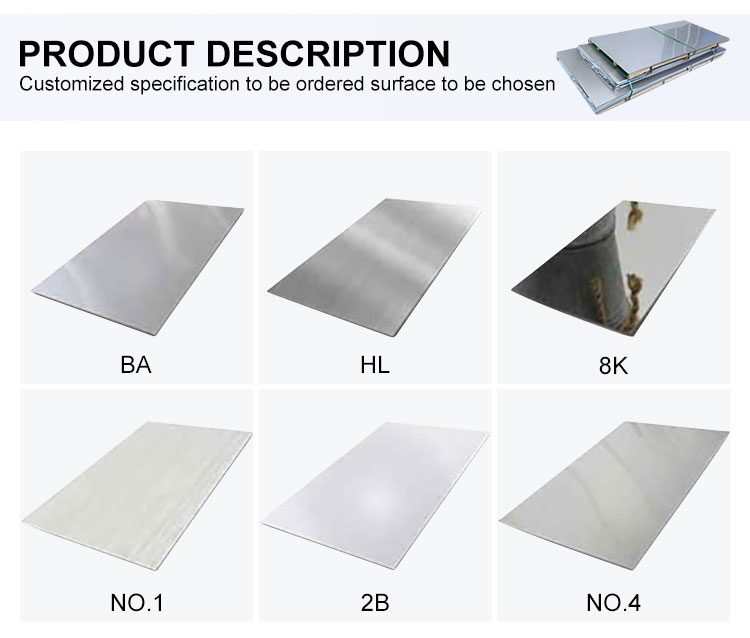

PRODUCT DESCRIPTION

AISI 347 STAINLESS STEEL SHEET / PLATE FOR SALE

Grade:06Cr18Ni11Nb;SUS 347;ASTM 347;X6CrNiNb 18-10;1.4550;2338

Surface: NO. 1, 2B, BA, NO. 3, NO. 4, HL

MOQ : 5 TON”CHOOSE PUXIN STEEL AND LOOK FORWARD TO HEARING FROM YOU!“

347 stainless steel plate is a high-performance austenitic stainless steel produced in accordance with American ASTM standards. Its main features are excellent corrosion resistance and high temperature oxidation resistance. It is widely used in aviation, chemical industry, power generation, petrochemical industry, food and papermaking, etc. field. 347 stainless steel plate is equivalent to 0Cr18Ni11Nb in Chinese standards, containing 18% chromium and 11% nickel. By adding the niobium (Nb) element, the material's resistance to intergranular corrosion is significantly improved, while the strength is enhanced without affecting the plasticity, making it suitable for structural parts requiring high strength and corrosion resistance.

PRODUCT PERFORMANCE

Features of S34700 stainless steel plate

Excellent corrosion resistance

High temperature oxidation resistance and corrosion resistance

Excellent high temperature performance

Multiple field applications

PRODUCT FEATURES

PRODUCT CHARACTERISTICS OF 347 STAINLESS STEEL PLATE

Excellent corrosion resistance>>347 stainless steel plate contains 18% chromium and 11% nickel to form a strong chromium oxide film, which has excellent resistance to acid, alkali, salt solution and oxidation corrosion, and is particularly suitable for harsh chemical environments.

High temperature oxidation resistance>>In high temperature environments, 347 stainless steel plates can maintain good oxidation resistance below 800°C, avoid the formation of oxides, extend service life, and are suitable for high temperature applications.

Excellent high temperature strength and creep resistance>>347 stainless steel plates have superior stress rupture and creep resistance under high temperature conditions, far exceeding 304 stainless steel, and are particularly suitable for structural components in high temperature working environments.

Enhanced intergranular corrosion resistance>>By adding niobium (Nb) elements, 347 stainless steel plates can effectively prevent intergranular corrosion under high temperature and stress environments, ensuring the long-term stability of the material in harsh environments.

Excellent weldability and formability>>347 stainless steel plates have good weldability and can be welded without reducing material properties. They are widely used in structural parts that need to be welded.

Wide range of applications>>Due to its excellent high temperature and corrosion resistance, 347 stainless steel plates are widely used in aerospace, petrochemical, electric power, food processing, papermaking and other industries, especially for key components in high temperature and corrosive environments.

PRODUCT PARAMETERS

PRODUCT PARAMETERS

| ELEMENT | C | Si | Mn | P | S | Cr | Ni | other |

| Minimum%(%) | - | - | - | - | - | 17 | 9 | 10C-1.10 |

| Maximum(%) | 0.08 | 1 | 2 | 0.045 | 0.03 | 19 | 12 |

PHYSICAL PARAMETERS OF 347 STAINLESS STEEL PLATE

Yield strength: ≥205 MPa

Tensile strength: ≥520 MPa

Elongation: ≥35%

Hardness: HBS ≤ 187, HRB ≤ 90, HV ≤ 200

SURFACE TREATMENT

PUXIN STEEL offers SUS347 stainless steel plates in a variety of thicknesses and sizes, ranging from 0.3mm to 6.0mm. We also provide customized cutting and surface processing services, including options such as mirror, brushed, and sandblasting finishes, to meet the specific needs of our customers.

APPLICATION

Aviation,

power generation,

chemical,

petrochemical,

food,

papermaking